Leading supplier of AAC production equipment on growth

Jiangsu Teeyer Intelligent Equipment Co., Ltd. is a high-tech enterprise specialized in building materials equipment designing, R&D, manufacturing, project management and integration of operation & maintenance. The main product of Teeyer is the whole line equipment for AAC block and panel production. Teeyer aims to provide customers with satisfactory overall solution for wall material products.

Located in High-tech Zone, Changzhou City, Teeyer Company set up in the year of 1989, with 214.3 million yuan registered capital, 143,000 square meters covering area, and over 400 employees, among them more than 80 administrative staff and senior R&D technicians.

Teeyer is the first national company realizing the localization of Aerated Concrete Production equipment in China, on the basis of absorbing and drawing lessons from foreign advanced technology, breaking the previous situation of completely replying on imports.

Up to now, Teeyer owns more than ninety patents related to AAC whole line equipment, and perennially keeps in the forefront of China AAC equipment exports.

Teeyer has established Jiangsu Enterprise Technology Center and Jiangsu Engineering Technology Center, undertaken several provincial and municipal science and technology projects. Teeyer participates in dozens of industry standards formulation, such as „AAC Cutting Machine“ standard, and is honored with “Quality Conformity Assessment”, “Top Ten Brands of Customer Satisfaction”, “Jiangsu Famous Brand”, “Changzhou „Specialized, Fined, Peculiar and Innovative“ Company, and “Changzhou Star Enterprises” etc. Teeyer successively completed ISO9001 quality management system certification, ISO14001 environmental management system certification and other system certifications.

David Chen, Executive VP at Teeyer, proudly reports on site: “Thanks to this successful merger with Elematic China, we are not only in the position to cover the domestic market with a gigantic product portfolio, but can also supply customers all over Asia and even Europe and the world.”

Numerous references across the globe

After over 30 years of development, Teeyer has established a mature production system and after-sale service system. The AAC block/panel making machine manufacturer built over 1,000 complete sets of AAC production lines, exporting nearly 150 production lines to more than 20 countries and regions around the world, such as Kazakhstan, Russia, Belarus, India, Indonesia, Vietnam, and so on, like following examples:

China: Taizhou Jintai Environmental Thermal Power Co., Ltd., Zhejiang Suonata New Walling Material Co., Nanjing Asahi New Building Materials Co., Ltd., Beijing BBMG Autoclaved Aerated Concrete Co., Ltd.,

Kazakhstan: Sensata Group,

South Korea: ES Group,

Indonesia: PT Superior Prima Sukses and Jl. Raya Ngawi Solo.

Teeyer product list

The complete product range for the AAC production is provided, starting with the raw material processing section to batching & pre-curing, automatic steel mesh fabricating & circulating section, the autoclaving section and cutting & grouping through the finished product classification & packaging:

Raw Material ProcessingSection

As the first part of the AAC block production line, the raw material preparation section includes several machines like jaw crusher, ball mill, bucket elevator, etc.:

Ball Mill: Raw material includes sand, fly ash and tailings to be milled into fine material, in order to meet the slurry standards.

Slurry Agitator: There is a transition slurry pool next to the slurry storage tank, with two functions: one is to pump slurry to batching area, the other is to make connection with each single tank.

Slurry Storage Tank: After ball mill, the slurry will be pumped to the slurry storage tank, the agitator of tank will work constantly to avoid slurry sedimentation.

Jaw Crusher: The jaw crusher is an important machine for the raw material preparation section. It is mainly used to crush lime into powder for AAC production.

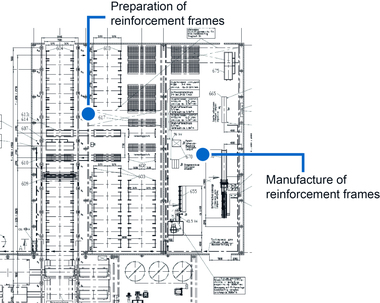

Automatic Steel Mesh Fabricating and Circulating Section

Mesh Welding Machine: The straightened steel bars are welded into steel mesh automatically, which is used for the preparation of AAC panel production.

Wax-dipping Lifting Device: Assembled steel frames with steel pins together to be lifted by this device, dipping into wax.

Dowel-Inserting and Dowel-Drawing Out Hoister: Assembled steel frames or steel cages are inserted in mold then pull out from mold by the hoister.

Mesh Assembly Frame Conveyor Line: This conveyor line (circulation conveying system) consists mesh assembly frame rack, mesh assembly frame ferry cart and other related devices.

Pouring & Pre-Curing Section

In the batching and pouring section, Teeyer offers a range of related machines including slurry scale, slurry storage container, aluminum powder mixer, ball mill, bucket elevator, and so on. The prepared materials will be mixed in a certain ratio, and then poured into the molds. After years of optimization, the batching accuracy is quite desirable.

Slurry and Powder Material Scale System: Sand slurry and waste slurry shall be measured by electronic scale, while cement and lime shall be measured by powder scale according to the proportion requirement.

Pouring Mixer: The pouring mixer is one of the core equipment for the AAC block machine. It is a combination of mixing equipment and pouring machine, and can mix all the materials needed in a very short time. For the production line, the main materials in the pouring mixing machine include fresh slurry, waste slurry, lime, cement, gypsum and aluminum powder.

Aluminum Powder Automatic Measuring And Mixing System: Aluminum powder is measured according to a set value and then put into the pouring mixer automatically. In the AAC production line, the aluminum powder mixer is used as a blending machine to mix the aluminum powder with the slurry.

Up-and-down Pouring Device: The up-and-down pouring device is a key unit of the AAC block pouring machine. It comprises pouring nozzle, lifting arm, and air compressor cylinder.

Cutting Section

The pre-cured concrete block in the mold will be cut into pieces as needed by the AAC cutting machine. The block appearance is largely affected by the performance of cutting machines. Due to the effective work by the subsequent machines like tongue and groove milling device, vacuum suction hood, and tilting table, each block will get 100% ready for autoclaving.

Cross Cutting Machine: Followed by horizontal cutting, it is cross cutting area. The cake will be cut in vertical as required value. As the core equipment in an AAC production line, the cutting machine, comprising a vertical cutting device and a horizontal cutting device, can cut the AAC from all 6 sides. Thus the blocks or panels could be accurately cut into pieces with a certain dimension.

Vertical Cutting Machine: After side cutting area, it is horizontal cutting. The horizontal cutting machine will cut the cake into several layers according to the set value.

AAC cutting car system: works around the cutting station. It consists of a cutting car, pinion and rack moving rail. In the cutting section of the AAC production line, this cutting equipment can convey the green cake and the side plate from the turning hoist to the tilting table.

Tongue and Groove Milling Device: Cutting cart carries side plate and cake to the tongue & groove area, to cutting the cake both two sides. Generally, the width of block is 600mm, and the width of panel is 608mm. For panel, it will have an extra cutting on groove.

Autoclaving Section

The autoclaving section is a critical part of the entire AAC production line. It includes traction mechanism, ferry push car before/after autoclaving, AAC hardening car, and autoclave. Aerated concrete blocks will be autoclaved in the high temperature and high pressure environment provided by autoclave, a high pressure vessel.

Traction Mechanism: very important to the fluent operation of the AAC production line. It can push or haul the mold in the pre-curing section and hardening car before and after autoclaving section.

Ferry Push Car Before/After Autoclave: The driving part of ferry cart carries the autoclaved cake, to connect the autoclaving cart automatically, then pulling the cake out of autoclave.

Hardening car: located at the autoclaving section, is used for the material conveying in the AAC production line. It can endure the high temperature and high pressure environment in the autoclave, and won’t get jammed or deformed.

Autoclave: The cut cake completes a hydrothermal reaction of CaO-Si02-H2O in the autoclave, experienced four processes, which are vacuuming - heating - constant temperature - cooling, and the final products. Finally, AAC blocks or panels are produced. The autoclaving cycle is around 10-11 hours to give the blocks/panels enough strength.

Finished Products Packing Section

As the last unit of the Teeyer AAC block manufacturing line, the packaging section mainly comprise three machines, AAC block separator, finished product clamping hoist, and AAC block conveyor line, and so on. The highly automized process features high productivity and low labor intensity.

Separator: to separate the sticky cakes into several layers, the finished products are blocks or panels.

Finished Product Clamping Hoist: Finished products will be lifted by clamping hoister, to leave side wall behind, and the side wall will be transferred to a next cake production.

Rotating Hoister: Finished squeezed, blocks will be lifted by rotating hoister, on the length 1.2m direction, after 90 degree rotating, the blocks will be put in cross directions on the pallet.

Finished Product Conveyor Line: for block conveying at the packaging section. As a chain conveyor, it comes with a stack merging device, and works together with the finished product clamping hoist and automatic strapping machine to pack the AAC blocks.

Production Control System

Production Control System: DCS automation control system is composed of Siemens PLC hardware, that is decentralized control and centralized management mode, low failure rate and easy for maintenance.

All devices with the decentralized control system are equipped with on-site local control system, which can independently operate and monitor the machine in real time.

CONTACT

Jiangsu Teeyer

Intelligent Equipment Co., LTD

No. 312 West Hehai Rd., High-tect Zone

Changzhou, Jiangsu/P.R. China

teeyer@teeyer@com