Lightweight concrete for Germany‘s most powerful district heating facility

Central element of the new geothermal facility in Munich Sendling is the new functional building, feeding the district heating network with energy generated from within the earth. Liapor lightweight concrete being 50 cm thick was used for the construction of the new building. Thanks to its insulation properties, the building material provides for the fact that no undesirable condensation water precipitates into the interior of the building, while protecting the environment against disturbing noise simultaneously. It is the most powerful facility in Germany at present, that will supply eco-friendly heat for more than 80,000 people in future. The new functional building includes a building unit for electricity, the pump station, and the thermal water building.

Moisture under control

The special feature of the new building designed by Straub Architekten based in Munich is the reddish, horizontally textured building envelop made of Liapor lightweight concrete. The building material was chosen for clear reasons: „We have decided in favor of lightweight concrete in order to protect the interior of the building against condensation water, thus ensuring that no moisture precipitates, especially at the building corners. This is achieved by the particular insulation properties of lightweight concrete, and was examined under building physics‘ aspects beforehand,“ explains architect Thomas Straub (Dipl.-Ing.). „Another point for using lightweight concrete was the fact that it allows realizing an effective sound protection to the outside. Ultimately, very high sound levels will occur inside to some extent, against which the neighboring, partly inhabited areas need to be protected.“

Demanding concrete pouring process

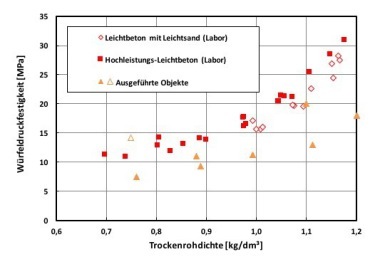

A total of 800 m³ of Liapor lightweight concrete LC25/28 D1.6 was used in construction of the building envelope. The concrete was manufactured and delivered by the Heidelberg Materials Beton DE GmbH plant Zamilastraße/Munich; construction works were carried out by Pfeiffer Baugesellschaft mbH in Rosenheim as general contractor. On site, the Liapor lightweight concrete was poured with the aid of concrete buckets and compacted in concreting sections of up to 6 x 8 m. The easily workable consistence of the lightweight concrete with the lightweight aggregates made of expanded sand and expanded clay facilitated the workflow, as well as the relatively fast strength development.

For implementing the requested fluted surface structure, reusable textured formliners of type 1/316 B Pennsilva made by Reckli were inserted into the supporting formwork and perfectly aligned in horizontal direction. The outcome is a smooth surface with a jointless appearance in fair-faced concrete class 4, on which only the contours of the formliner elements become slightly apparent – as intended – (vertically arranged elevations with a coarse fracture pattern, separated by 7mm wide depressions). The entire shell construction was completed in eight months.

Special coloring, exceptional structure

In the preliminary stage, Betotech Baustofflabor GmbH, Munich Area, had made seven different sample walls of 5 m² each in order to ensure coloring of the lightweight concrete in a reddish shade based on iron oxides. The color shade played an essential role in terms of design: „The new building is situated in the neighborhood of existing brick buildings from the fifties and also quite close to the Isartal railway station made of bricks at the turn of the century,“ states architect Thomas Straub. „With the building envelop colored in a reddish shade we intended to adapt it to the existing old building stock, but also interpreting its coloring in a modern way at the same time.“

The surface structure of the new building could be implemented as requested as well, as demonstrated by the delicate, horizontal lines of the building envelope. „They create a very nice interplay of light and shadow, but in combination with the formwork joints also provide for an altogether very homogeneous, consistent façade pattern,“ explains the architect. „We are completely satisfied with the project and, in particular, with the visual appearance of the exterior building envelope.“

Important contribution to carbon neutrality

The new geothermal facility will start full operations soon and will supply a huge amount of eco-friendly thermal heat into the local district heating network being more than 900 km long. It is an important step in increasing renewable energy sources and makes a crucial contribution to the goal of covering Munich‘s demand on district heating in a carbon neutral way by 2040 at the latest.

CONTACT

Liapor GmbH & Co. KG

Industriestr. 2

91352 Hallerndorf-Pautzfeld/Germany

+49 9545 448-0