Massive reservoir roof constructed with precast concrete

Precast concrete I-beams and hollow-core slabs were incorporated in the construction of 100ML reservoir at Contermanskloof, Cape Town/South Africa. Manufactured by CMA member, Cape Concrete, the precast elements were used for the construction of the structure’s 14,500m² roof.

Completed in April 2022, the reservoir was built by CSV Construction as the main contractor on behalf of the City of Cape Town.

The water storage unit is 160.5m long and 90.9m wide and its maximum water depth is 8.5m. The structure comprises an in-situ 200mm concrete floor flanked by 5.5m high 1:2.5 sloping concrete embankments topped with 4.6m high vertical retaining walls. The roof’s precast beam and hollow-core slab assembly is supported by 99 x 9m (height) x 700mm (diameter) in-situ concrete columns on elastomeric bearing pads.

The roof has an apex on the longitudinal centre line and slopes at 1:150 to the perimeter walling on either side for drainage. The first roof section was completed in August 2021 and the second was finalised in November 2021.

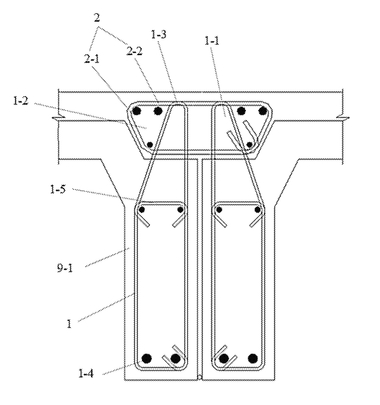

Hollow-core slabs supported by 108 I-beams

The hollow-core slabs are supported by 108 I-beams and the perimeter walling. The I-beams measure 13,5m (length) x 1.2m (height) x 500mm (base width) and the hollow-core slabs span 8.8m (length) x 1.2m (width) x 200mm (thickness).

The roof comprises 48 panel sections. Panel sections consist of two or three hollow-core bays with 11 hollow-core slabs in each. The panel sections are interlinked with transverse in-situ beams which run the full width of the structure; this creates larger panels and a more robust structure. Cast with a joint former between them, these beams also act as expansion joints.

In addition, the design includes three longitudinal expansion joints which run the full length off the structure. They too are filled with a joint former inserted in the gap between the opposing panel sections located above the precast beams. All the expansion joints are waterproofed with a flexible bandage.

The roof includes a 70mm mesh-reinforced structural topping cast over the panel sections to ensure proper shear transfer between individual slabs. The topping’s reinforcing was tied to the exposed reinforcing in the precast beams which added continuity to opposing hollow-core bays in the panel sections and increased the overall continuity of the roof structure.

The reservoir structure was designed by Peter Loubser and the structural team of Gibb Engineering in 2016, acting as specialist structural sub-consultants to WSP which was responsible for the overall contract. Initial site work was begun by a joint venture comprising NMC and Botes & Kennedy in 2017 but came to a halt in 2018 when both parties went into liquidation. Construction resumed early in 2021 when CSV Construction was appointed as the main contractor.

“We looked at the comparative costing of precast versus in-situ for the roof construction during the design stage, and precasting proved to be a significantly better option both in terms of cost as well as total programme time. In addition, it avoided the disruption that extensive support scaffolding would have caused,” said Loubser.

The roof includes several galvanised steel manholes to provide light during maintenance work inside the reservoir. Additional manholes are situated above the reservoir discharge and scour outlets for maintenance work.

Cape Concrete supplied the beams and pretensioned slabs

Cape Concrete was awarded the contract to manufacture the beams and 1 358 pretensioned slabs in 2017. “We had already cast 98 beams at the time of the shutdown in 2018,” said Cape Concrete director, Walter Botes. “So we decided to cast the remainder and store them in our yard until the project was resumed.

“The beams were prestressed and were cast on a single 75m soffit between the stressing heads. This enabled us to cast five beams on one soffit at a rate of one-a-day from Monday to Friday. We used five sets of end plates and one set of side molds, the latter being re-used for each beam casting. The beams were steam-cured so that the side shutters could be removed the day after casting. The beam cast on Friday reached 35MPa on Saturday which meant that all five beams were ready for de-tensioning.”

The roofing required 12,083m of prestressed hollow-core slabs and Cape Concrete used four 150m casting beds for their production in a strictly controlled quality protocol. They were cast with a 12.7m prestressed strands on four casting beds to yield a strength rating well above the required 50MPa and hot water was circulated under the casting beds to accelerate the curing process.

“The beams, which weighed 12,5 tonnes each, were installed with a 440-tonne crane (one of two in South Africa) with a 65m reach operating from outside the reservoir. We also used a 220 tonne crane and a 180 tonne crane for the installation of the hollow-core slabs. During the installation of the first roof section the cranes were positioned 17m away from the perimeter wall which complicated the installation process,” said Botes.

Sub-surface drainage system

The reservoir was built with a sub-surface drainage system to disperse ground water. It comprises a layer of no-fines concrete under the slab together with a combination of perforated pipes which follow the grid lines and drain into a concrete gallery which runs under the reservoir. All the pipes are clearly marked so that the source of any possible leakage can be identified. The concrete columns were cast after the main floor slab had been completed and the column reinforcing was tied in with the slab reinforcing to transfer the load through the column base to the slab. The sloping concrete embankment slabs were cast in sections using a back shutter system to prevent the concrete from slumping towards the bottom of the slope.

Rubber water bars, which allow for movement and prevent leakage, were installed on all the joints in the flooring and walling, and prior to completion the joints will be covered with a final waterproof bandaging system.

The embankments beneath the perimeter walling are being cement-stabilised to improve bearing and shear capacity and the outer walling is being backfilled to a metre below the top of the wall. A service road was built on top of the embankment.

When operational, the reservoir will be supplied by the Voelvlei Dam and Treatment Works via the existing delivery pipeline which passes by close to the site. The reservoir will ultimately feed Blouberg and other areas on Cape Town’s Western Sea Board with pre-treated water.

Text: David Beer

CONTACT

Cape Concrete Works

Wimbledon Road

Blackheath 7580

Cape Town/South Africa

+27 21905 1200