Monitoring of precast concrete constructions based on a new kind of sensor solutions

Damages caused on concrete constructions range from simple crack formation through to the ingress of water, corrosion damages, defective building joints and surface damages. With the aid of resistive and capacitive sensors, which are embedded in the precast component directly during the manufacturing process, there is the possibility of material-integrated strain and moisture monitoring.

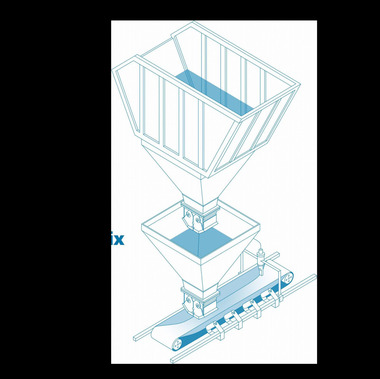

For realizing strain measurement, among others, embroidered sensors are applied which are manufactured in a Tailored Sensor Placement process. The measuring wires are incorporated in textile fabrics, with embroidery shapes and sizes of the sensitive surfaces being freely selectable, and the resistance varies depending on the layout. The standard sensors made of constantan identify both tensile load and compressive load up to 3 % cyclically. In addition, elastic sensor wires with a high elasticity and sensitivity made of shape-memory alloy are used which are able to detect changes in the material of up to 8 % elongation. These, however, do not need a fabric ground, the implementation takes place thermically. An analysis unit for permanent monitoring of the concrete matrix converts the mechanical strain into electrical signals. Continuous monitoring of the strain, the natural frequency and the entire range of frequency allow the detection and evaluation of structural damages.

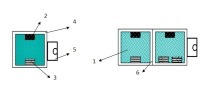

A microcontroller-based system, the so-called “TexMessBox”, serves for the diagnostics of moisture in concrete components and screed components; this system allows for a wireless communication between the monitoring staff and structural components being at risk, pre- damaged and/or damaged and already repaired. Highly sensitive sensor electrodes are detecting even finest changes of moisture in walls, ceilings, and floors. The sensor technology is entirely non-destructive and is incorporated in concrete or screed during casting or subsequently through drill holes in defined measuring spots. Long-term monitoring ensures a precise fault analysis.