Polarmoist – aggregate moisture measurement sensor

Polarmoist is an outstanding optical moisture sensor designed for detecting moisture contained in concrete aggregates. The sensor embeds a micro-processor and uses LEDs as light sources. It is used to detect moisture in moving samples. Non-contact, remote measurement ensures stable performance and a long service life of the sensor.

Wet aggregates may contain moisture in excess of what is desirable to keep the water-cement (w/c) ratio within design limits without overdosing cement. In practice, the moisture content of aggregates must be known to fractional percentages to minimize variations in concrete quality and to enable optimal usage of cement. Accurately measured moisture in aggregates makes it possible to optimize strength, durability and shrinkage of concrete products. Also, knowing the right moisture content prior to mixing permits shorter mixing times when the need to add water during mixing is eliminated.

Background

Currently, the moisture measurement method most widely used in the concrete industry is based on capacitive or microwave sensors. Capacitive and microwave sensors are typically installed in direct contact with the aggregate. Direct contact to samples causes mechanical wearing of the sensor, thus requiring occasional recalibration and finally replacement of the sensor. Optical measurement of material moisture permits non-contact detection with clear advantages for the concrete industry.

Performance

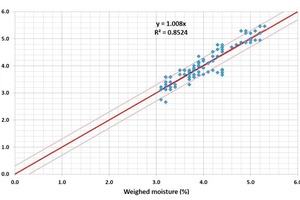

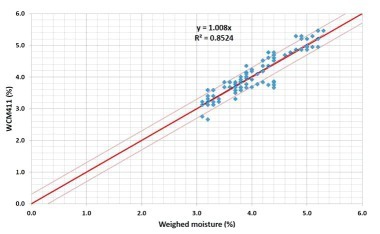

Figure 1 (p. 162, left) shows the results of a long-term test in a plant environment. Data was collected over a four-month period, leaving the optical sensor untouched during the entire period. The weighed reference values were collected by typically taking three manual samples from a mixing batch.

The apparent scatter in the data has clearly increased as compared to calibration data. However, the standard deviation, 0.25 % in moisture, is still fairly low. Surprisingly, the most significant reason for the scatter is not related to the performance of the optical sensor but instead to manual sampling problems of the weighed reference data.

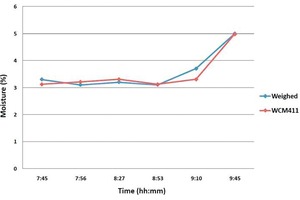

Figure 2 (p. 162, right) shows an example of a sudden variation in aggregate moisture. Reference values and sensor readings revealed stable moisture rates of about 3.2 %. Suddenly, both readings started to increase to 5 % and above. This example shows why it is important to monitor aggregate moisture continuously instead of taking only one reference sample per day.

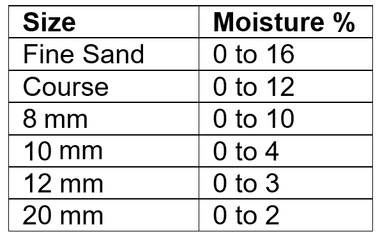

Polarmoist has been extensively tested in concrete plants with different grades of rock material. Appropriate calibration increases the accuracy of measuring water content compared to manual reference measurements in the case of a limited number of samples and a large variation of moisture in a given batch.

Features and benefits: Remote optical measurement of moisture content, no moving or wearing parts, high accuracy and resolution, fast response, stable LED light sources, easy to install and calibrate.