New air-coupled ultrasonic test methods for the building materials industry

Continuous, non-destructive quality testing during an ongoing production process is a real challenge for the concrete and ceramics industries, brick manufacturers and building materials producers as well as for other industries. Therefore, solutions for non-contact testing of materials and products that are difficult to examine are being developed at the Ultrasonic Research Center (FZ-U - Forschungszentrum Ultraschall).

For this purpose, the scientists in the town of Halle (Saale) rely on air-coupled procedures which are especially conceived for the respective application for the first time at all or are modified according to the specifications of the user. Even mass products such as concrete elements, ceramics, bricks, but also products made of plastics, composite materials, leather and even noble metals can be precisely examined for flaws and contaminations. Always in the focus: the compatibility of the new solution and the operational environment. Before the user makes far-reaching decisions regarding investments, in most cases, the industrial researchers investigate the general feasibility of the project, including the required pre-conditions and foreseeable costs, thus minimizing the economic risks by means of limited expenditures.

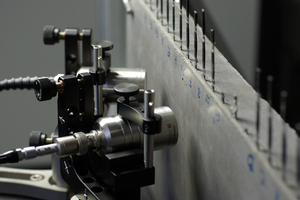

With its innovative approaches, the institute enables testing procedures which have so far not been possible or have only been practical to a limited extent. Using air-coupled ultrasonic, now larger surfaces can be scanned fast and completely, too. The resulting 2D color image visualizes flaws and defects precisely. Moreover, the investigation of e.g. ceramic products can already take place before the sintering process: consequently, inferior green bodies no longer end up in the kiln at all; this means energy savings of up to 10 %.

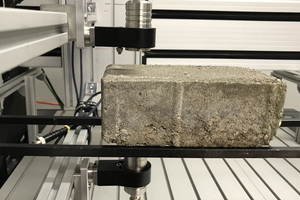

In most cases, testing initially is conducted by way of samples in the institute’s laboratory. If size or weight of the specimen – large-sized construction elements or even complete fiberglass boats, for example – do not allow it, a Europe-wide unique service takes effect: The experts of the FZ-U load their scanner into a transport vehicle and conduct the feasibility and object investigation on site in the customer‘s industrial environment directly.

When the scanner comes to the test specimen

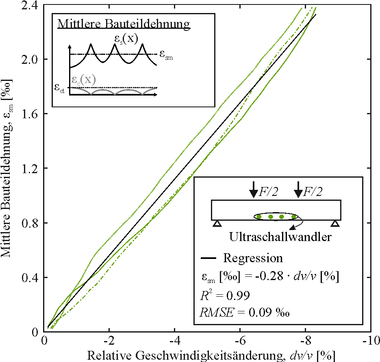

Recently, FZ-U presented an own developed method for measuring of sound velocity values: For the first time at all, reliable assessments giving specific numerical values are possible, whether the density values and the homogeneity values of the material at once are qualitatively in the requirement range.

This also entails advantages in the production of cement or bricks: If the ceramic lining of the kiln does not exhibit the proper density unperceivedly, this impairs its insulating effect and thus the product quality. The thermal load of defective insulating bricks faster results in defects, maintanence expenditure and an increased failure risk.

The methods for air-coupled ultrasonic testing are easy to integrate into the industrial environment thanks to the non-contact mode of operation that is free of radiation and allow for high testing speed even during transport on the conveyor belt. Instead of just random tests, in general, the method enables continuous zero-defect quality control.

According to their own information, all elements of the technological chain are available under one roof at the industry-associated research institute that is the only one specialized in air-coupled ultrasonics across Europe. Software modified according to customer-specific requirements or hardware adapted to a project, if required, come from the experienced industry partners like Sonotec, the international leader in air-coupled ultrasonic technology.

CONTACT

GF Forschungszentrum

Ultraschall gGmbH

Köthener Str. 33A

06118 Halle (Saale)/Germany

+49 345 44583910