New DBV Code of Practice on “Pre-Applied Bonded Membranes” – a module for a regulated type of construction

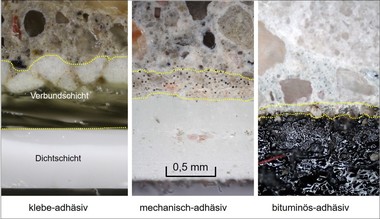

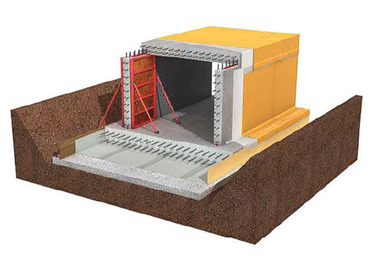

The sealing effect of the “pre-applied bonded membrane” type of construction is based on the full-surface waterproof bond bet-ween the pre-applied bonded membranes and the fresh waterproof concrete. The pre-applied bonded membrane type of construction includes the waterproof concrete structure, the pre-applied bonded membranes, and the pre-applied bonded membrane system accessories.

There is as yet no set of coherent guidelines and standards for the pre-applied bonded membrane systems that could have developed into generally accepted engineering practice. The safety of use of a pre-applied bonded membrane system is therefore not a given for the parties involved in construction. It is the objective of the new DBV Code of Practice on “Pre-Applied Bonded Membranes” [1] to fill this gap in the guidelines. Experiences gained in the real-life use of pre-applied bonded membranes and research findings have been taken into account [2,3,4]. The code of practice includes the required definitions as well as specifications and recommendations for testing, designing and realizing pre-applied bonded membrane systems. A “general verification of applicability” (“allgemeiner Anwendbarkeitsnachweis”; aA-FBVS) is defined for this type of construction, which requires verifications and tests to be provided for classification into three performance classes (depending on the maximum design water pressure of 3 m, 10 m, 20 m). In addition to 22 mandatory basic tests, 7 optional performance characteristics with tests are also proposed.

folie - Grundlagen zur Erstellung eines Regelwerks für eine innovative Bauart. Abschluss-bericht Forschungsinitiative Zukunft Bau,

Band F 3183. Fraunhofer IRB Verlag, 2020.

wasserundurchlässigen Baukonstruktionen aus Beton. - In: Betonkalender 2023,

Band 1, S. 155-184.