Pre-applied bonded membranes -

Avoidance of errors in planning and execution

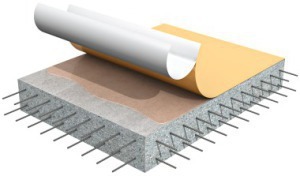

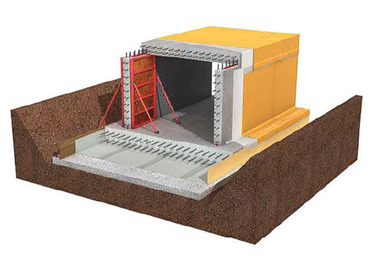

Pre-applied bonded membranes are used as additional or precautionary waterproofing measures for waterproof concrete structures. They can be used especially for geometrically complex, constrained waterproofing structures or in cases of high-value use and limited accessibility. Pre-applied bonded membranes are installed before concrete placement. When properly installed, they form a tear-resistant and waterproof bond with the concrete, preventing lateral water migration to adjacent separation cracks. The planning of pre-applied bonded membranes must be carried out together with the overall waterproofing planning and requires numerous preliminary considerations.

Pre-applied membranes are not considered equal to conventional waterproofing membranes following DIN 18533 but represent a particular type of construction due to their bonding effect. The German “Beton- und Bautechnikverein e.V.” (DBV) has published an initial status report and recommendations for action on the construction method in issue 44 (“Heft 44”), which for the first time summarizes a coordinated opinion for Germany. A DBV Code of Practice is currently being prepared.

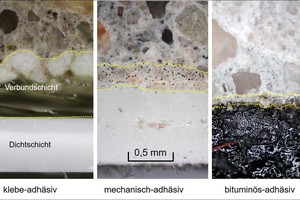

More than a dozen pre-applied membranes made of plastics or elastomer modified bitumen are available in Germany with different structures and composite effects: Adhesive, mechanical (e.g., nonwoven), or bituminous-adhesive. The bond must be present within the area of the sheet but also at joints. However, it may be compromised by cement slurry, soil, leaves, release agents, sawdust, puddles, ice, insufficient compaction, or inappropriate fresh concrete consistency during construction or during the laying period up to concrete placement. The professional installation of pre-applied membranes and seam joints and the avoidance of bond disturbances during the construction process, therefore, place high demands on the construction personnel.