New welding line successfully commissioned at

Mega Holding in Georgia

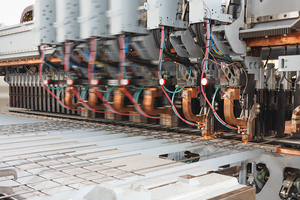

The market leader for the production of a wide range of precast concrete elements, based near Tbilisi in Caucasian Georgia, has purchased the newly developed ERM-ECO welding line from Austrian machine and plant manufacturer EVG. Just a few months later, both sides can look back with satisfaction on a rapid installation and commissioning and are pleased with a production performance that has even exceeded their already high expectations.

The right investment decision at a challenging time

Following the company‘s foundation in 2017 and steady growth in the production of high-quality slab and wall systems, beams, columns and the like, it now employs 150 people. The modernization of the reinforcement production is another milestone in the positive development of Mega Holding.

“The decision in favor of EVG was easy to make after comparing not only prices, but especially performance guarantees from several suppliers,” says General Director and co-owner Vazha Manascherov. “In addition, our project team quickly realized that EVG, with this development and its focus on fully automatic operation from coils with wire diameters of 5 to 16 mm and flexible line wire spacings of over 50 mm, had exactly met the current requirements of our industry. With the ERM-Eco welding system, there are no changeover times for product changes, which means that we are able to react very efficiently to the ever faster changing requirements of the market and to meet our entire ‚just-in-time‘ requirements.“

EVG also presented the extraordinary flexibility of the new ERM-ECO via a live stream at this year‘s WIRE trade fair in Düsseldorf. The impressed visitors were given the opportunity to design meshes in different geometries, e.g. with cut-outs or different wire diameters, on site, transfer them online to the production line and produce them immediately in perfect quality.

EVG is addressing the ever-increasing importance of energy with the new Ecoweld medium-frequency direct current welding technology, which guarantees uniform and standard-compliant weld joint strength with minimal energy input.

Experience and quality awareness on both sides

EVG‘s decades of experience as a supplier of systems of various designs for the manufacture of concrete reinforcement products also proved to be a great advantage during installation and commissioning. As a result, all work was completed on schedule and production was ramped up on time. In addition to reliably covering its own requirements, Mega Holding is already supplying external customers with welded special reinforcement elements of the highest quality.

It should not go unmentioned that the popular Inside EVG (April 4-14, 2025) will again be offered parallel to next year‘s bauma trade fair. Once again, one of the highlights will be the live presentation of an ERM-ECO, with considerably enhanced functionality.

CONTACT

EVG Entwicklungs- und Verwertungs-

Gesellschaft m.b.H.

Gustinus-Ambrosi-Str. 1-3

8074 Raaba-Grambach/Austria

+43 316 4005-0