Resistance of carbon reinforcement to hydrophobation

Steel-reinforced concrete is used by the construction industry all over the world. But it has one weakness: its reinforcement is subject to corrosion. To minimize this risk, it is sometimes protected by hydrophobation. Carbon concrete does not have this weakness – it may nevertheless be advisable to protect this innovative construction material from ingress of water and, in this way, from frost damage. Solidian, in collaboration with Panta Ingenieure GmbH, has examined the effect of relevant chemicals on carbon reinforcement.

Steel-reinforced concrete is highly regarded for its high strength and versatility. It has, however, one weakness: water can penetrate the pores and cracks in the concrete and promote corrosion of the steel reinforcement. This negatively affects the loadbearing capacity of the construction and frequently leads to expensive repairs or even loss of stability. To reduce water absorption by the concrete, it can be treated with water-repellent agents: i.e., hydrophobized. There exist various procedures. One of these is addition of special agents during concrete production. Impregnation and surface treatment are also possible. Chemicals such as silanes and siloxanes are used (see text box left).

Carbon concrete

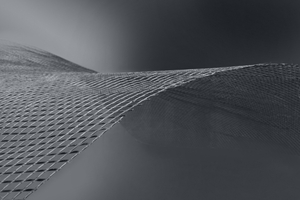

The reinforcement of carbon concrete, as opposed to steel-reinforced concrete, consists of materials that do not corrode. A minimal concrete cover to protect the reinforcement is therefore sufficient. This considerably reduces the amount of concrete required for many applications. In combination with the very high tensile strength of carbon concrete, loadbearing concrete construction elements with a thickness beginning at only 30 mm are possible. This reduces the use of cement and aggregate and contributes to improving the environmental balance.

This furthermore offers advantages with respect to transport, construction time and utilization of space, to mention only a few benefits.

Carbon concrete, moreover, is highly resistant to chemical attack, saltwater and wear. It is therefore extremely long-lasting and durable, even without a surface-protection system. To ensure that hydrophobation has no negative effects on carbon reinforcement, Solidian, in collaboration with Panta Ingenieure GmbH, conducted relevant experiments.

Tensile strength

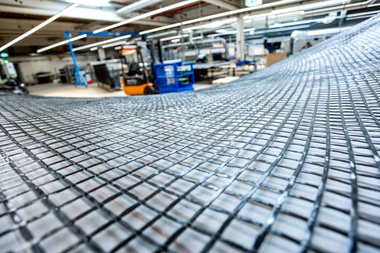

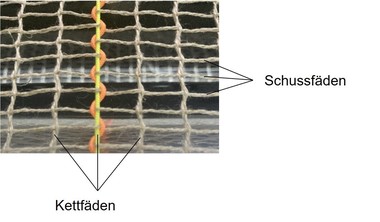

For hydrophobation, the test personnel in charge of the experiments choose four different impregnation systems provided by leading manufacturers for the test (see text box below). To obtain representative results, the tests were performed on Solidian Grid (Q71-CCE‑51). This material of the reinforcement mesh is physically identical to other epoxy-resin impregnated carbon mesh reinforcement supplied by Solidian, with the main difference being the geometry.

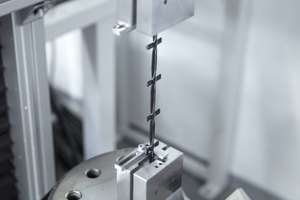

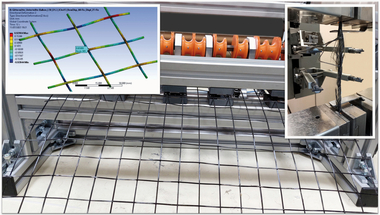

At the beginning of testing, the initial tensile strength of the carbon fiber strands was determined based on ISO 10406-1:2015-0. The specifications for testing the durable resistance of non-metallic reinforcement to various chemical influences have not yet been entirely standardized. ISO 10406-1:2015-01 also describes, in addition to the tensile test of the fiber strands, an aging process for evaluating the resistance to alkali-ions in the concrete.

Assessment procedure

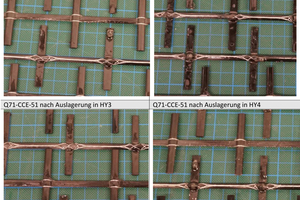

The team from Solidian applied this technical approach for the present experiments and stored the fiber strands in the hydrophobation media for 30 days at 60 °C. The test specimens were photographed to assess any optical changes. Test storage in a temperature-controlled hydrophobation media affects the fiber strands more than does actual use in a structural element, since higher temperatures promote possible chemical decomposition processes. It is assumed that 30-day accelerated aging under these conditions simulates a service life of several decades.

After the laboratory team had removed the fiber strands from the hydrophobation, they rinsed them with tap water, surface-dried them and stored them for at least 48 hours under laboratory climate conditions. Subsequently they were again photographed.

Based on the photos, the test personell conducted a before and after comparison. They determined that, apart from slight sedimentation on the surface, no signs of aging or separation were apparent. In case of separation, the otherwise shiny carbon fibers appear dull. This was not observed in this case.

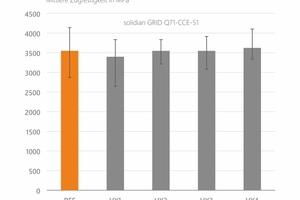

Fig. 1 shows the results for average tensile strength as well as minimum and maximum values of the respective test series. Prior to the hydrophobation treatment, the average tensile strength of the Solidian Grid ranged around 3,550 MPa. After hydrophobation, the average tensile strength varied approx. 5 % around this reference value. The lowest average tensile strength was measured at 3,370 MPa for the product from Wacker Chemie. This minimum value resulted from a low individual value in the test series, which per hydrophobation process consisted of a total of five experiments. At this test, the carbon reinforcement showed no significant changes in strength or in visible characteristics on the surface.

Conclusion

The test revealed that hydrophobation does not significantly influence the long-term durability and strength of carbon reinforcement. Accordingly, concrete can without any reservation be treated with it. It is advisable to observe the recommendations in the DiBt Technical Guideline on Maintenance and from Schiessl-Pecka/Strehlein for planning, execution as well as construction supervision and quality assurance.

CONTACT

Solidian GmbH

Sigmaringer Straße 150

72458 Albstadt/Germany

+49 7431 10-3135