Reuse and circularity of lightweight concrete products

Since resources become increasingly scarce, the circularity of construction products is of paramount importance, besides extending the service life of structures. Lightweight concrete products, particularly wall panels, provide a high degree of circularity.

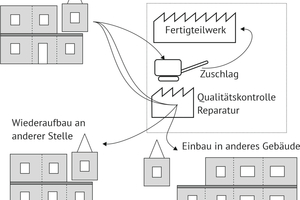

Three scenarios (Fig. 1) exist with respect to implementing a circular economy approach. The first is that lightweight concrete walls are easy to separate during deconstruction thanks to their low reinforcement ratio, and that they can be subsequently fed back into the processing cycle as lightweight aggregate. This method is already being used at precast plants.

Another, much more sustainable method is to reuse entire structural components or to re-erect the building in a different location. This will not pose any engineering problems provided that the right design for vertical and horizontal load transfers is chosen. Lightweight concrete walls installed in combination with uniaxially restrained floor slabs, for example, are easy to disassemble by removing the peripheral tie and wall-to-wall connections.

In Germany, however, this approach still poses challenges in terms of applicable building regulations; yet there are workable solutions particularly for lightweight concrete walls. One of these options is for the manufacturer to take back the wall, to have it inspected like a used car to confirm that it complies with current rules and standards, and to attach a new CE mark. To do this, however, it is necessary to know where and how the wall was manufactured at the time. This could be done, for example, by attaching a unique serial number to the wall. A third party could perform this process if the original manufacturer is no longer available. The advantage of this method is that even with a used wall, the customer will receive a reliable product that has a very small carbon footprint thanks to its reuse.