Reymann Technik realizes the most modern pallet circulation system in North America

In Florida, what must currently be the most modern pallet circulation system in North America has gone into operation for production of precast concrete elements for residential construction. Reymann Technik realized the project as planner and general contractor – the largest project in the history of the engineering firm.

In Florida, according to the supplier, what must currently be the most modern pallet circulation system in North America has gone into operation for production of precast concrete elements for residential construction. The Villages, one of the major real estate developers in the United States, is setting a historical milestone by changing over to precast concrete elements. Reymann Technik implemented the project as planner and general contractor – as the largest project in company history.

The name The Villages stands for one of the largest housing estates for people aged 55+ in the United States. The estate extends over three counties, approximately 90 km northwest of Orlando in Florida. Now more than 150,000 residents already live here, and the community continues to grow. Spending retirement years with a high standard of living and in a safe community and in the mild climate of the Sunshine State is what makes The Villages so attractive for many US Americans.

Most of the single-family homes were until now built in conventional timber frame construction or by the “brick on brick” method – a very successful concept for decades. But the participating companies nevertheless wanted to take a possible switch to precast concrete elements into consideration. On average, 2,500 workers completed some ten homes per day by conventional building methods. The objective was to develop, together with the participating architects, consultants and planners, a construction system based on precast concrete elements, in particular to save manual labor and, at the same time, to reduce construction times for building homes of even higher quality.

Development of an effective construction system

The greatest challenge and at the same time the decisive success factors in realizing a system of the envisioned kind were, among others, the development of an effective construction system, automation and reduction of manual labor, use of trained personnel and a long-term planning horizon. In 2019, Reymann Technik was commissioned, as general contractor, to plan and realize a pallet circulation system for The Villages. By now, phase 1 of the system has gone into operation. The precast plant in Governor Rick Scott Industrial Park is, according to the supplier, the production plant with currently the highest degree of automation for precast concrete element production in North America. A second expansion stage, phase 2, is already in planning. Production with a total of three halls from phase 1 takes place on a floor space of approx. 650 x 220 feet (approx. 200 x 68 meters). The product program comprises solid walls (interior and exterior walls), insulated exterior walls and supplemental columns/pillars.

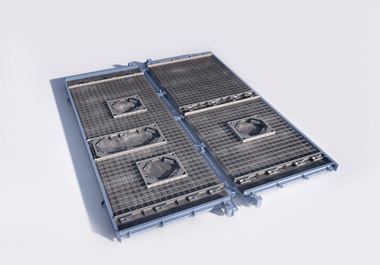

Initially, a single type of home was adapted to the precast concrete construction method. However, the circulation system is so flexibly conceived that individual homes can be built – in extreme cases, including one-offs. The walls are connected to the foundation by reinforcing bars and sheathing pipes. The wall connections in accordance with the applicable building code are executed with loop boxes and casting recesses. The exterior walls will be provided with insulation. For this purpose, the reinforcement was adapted to a special lattice-girder system into which the insulation is integrated. Currently, primarily standardized wall heights of eight feet (approx. 2.5 m) and ten feet (approx. 3.0) are being manufactured, including the required pitched gable walls. There is flexibility for variable wall heights of 12 feet, one inch (approx. 3.7 m).

Automation and reduction of manual labor

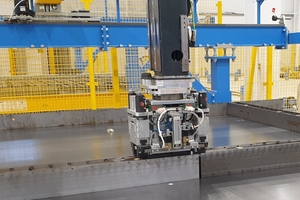

The Progress Group was commissioned with providing the mechanical equipment. The plant combines the current state-of-the-art in terms of automation – in addition to complete robot-supported formwork logistics. Fully-automated steel processing including a mesh-welding plant was also installed. Concrete production, procurement and casting were also planned to be automated. Workstations for manual formwork supplementation and reworking were generously designed, including six stations with laser projection to reduce plotting to a minimum, and thereby to save time. In addition, three pallet lines for finishing the concrete surfaces are available. The completed walls are automatically transported out of the hall by commissioned wall transport racks, and then by mobile portal crane on to storage.

Two additional halls are currently already planned as expansion stages. The performance of the plant is being increased step by step and lies currently at 19 homes per week, with an average of 2,000 square feet (approx. 186 square meters) per home, and will be increased to 30 homes per week.

Special features of formwork technology

As basic formwork for the variable wall contours, robot-compatible steel forms (SAS Standard Automatic Formwork) from Ratec are used on the pallet circulation. They are perfectly tailored for use on the completely automated formwork logistics, including demolding, storage and formwork robots as well as automatic cleaning. The SAS forms are covered with sheets during casting to protect the magnet buttons (switching mechanism) from penetrating concrete. The cover sheets are positioned prior to casting and can once again be removed after finishing.

The required manual work includes placement and removal of special formwork for doors, windows and standardized recesses. A shrinkable steel form, which has already proved effective in practice for windows both for horizontal and vertical production, is used for door openings. Handling takes place by crane and load-lifting magnet. The advantage of this solution is that relatively few individual parts must be handled. The recess former is positioned and lifted in one piece so that here, too, manual work of the plant personnel is reduced.

Casting of complete windows

The specifications for windows provided that they are to be directly cast in, with the result that a reliable solution for fixing them in place was required. Direct casting in of windows is not possible with the current state of the art in most cases. However, since the windows involved in this case were sliding windows, Ratec was able to work out a solution. The formwork consists of a lower part fixed to the pallet by a magnet, onto which the window is placed. Subsequently, an upper part is placed onto the window and screwed to the lower part. The special formwork protects the windows from dirt and damage, including the glass segments, during the entire production process.

At this stage, formwork for eleven window types and five door varieties are used. For precise positioning, the formwork robot places two each positioning magnets onto the pallet, onto which the respective formwork for the door and for the windows is placed. This procedure ensures correct positioning by preventing setting the wrong formwork, which reduces imprecision and facilitates the work of the plant personnel.

Reymann Technik continues its support for the customer. “Our work does not end when the plant goes into operation or after official acceptance,“ emphasizes Jörg Reymann, Managing Director of Reymann Technik/Ratec. “We want to make sure that the processes are designed in such a way that our customer stand to profit from an investment of that kind as soon as possible and successfully over the long term.”

CONTACT

DZ Precast Solutions, Inc.

5860 Holland Parkway

The Villages

FL 32163/USA

Reymann Technik

Karlsruher Str. 32

68766 Hockenheim/Germany

+49 6205 9407-0

Ratec GmbH

Karlsruher Str. 32

68766 Hockenheim/Germany

+49 6205 9407-29

Progress Group

Zeil 127

60313 Frankfurt am Main/Germany

+49 69 77044044