Sebastian Müller AG‘s new wetcast production line

designed for the manufacture of landscaping products

Sebastian Müller AG, based in Rickenbach in the canton of Lucerne in German-speaking Switzerland, is specialized in the manufacture of concrete products for the building, civil engineering, road construction and landscaping sectors. Facade and staircase elements, as well as pillars, are also produced on request.

Sebastian Müller AG recently selected the French automated equipment manufacturer Quadra to design and develop a new wetcast production line.

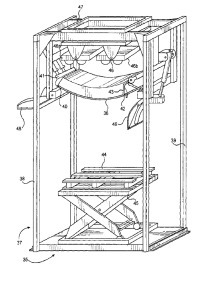

This flexible, multi-purpose production line is dedicated to the manufacture of a wide range of outdoor landscaping products, including kerbs, fences, garden tiles and steps. It comprises an automatic stacker crane, a concrete feed unit consisting of a flying bucket and a dosing hopper, a curing area and five workstations, including two for automated mold filling and three for demolding and mold preparation.

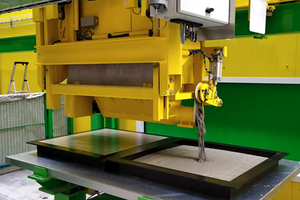

Automated mold filling solution

The concrete is led from the mixer to the dosing hopper by means of a flying bucket. A probe controls the automatic supply of concrete to reception hopper. The concrete is discharged by a helmet whose opening/closing controls are controlled by the dosing hopper, on load cells, located below. An endless screw empties the dosing hopper. When a mold is being filled, a watertight valve closes as soon as the set weight is reached. The dosing hopper can move in all three directions to fill the full range of molds on the trays.

The position of the dosing hopper as close as possible to the mold varies according to the height of the product to be filled, to avoid splashing. A dedicated position with secure cycles and access platforms is provided to facilitate daily cleaning.

Each tray is assigned a production recipe indicating the number of molds to be filled, the corresponding quantity of concrete and the definition of the dosing hopper‘s trajectories. This fully automated solution ensures mold filling accuracy of around +-100 g.

Mold support trays handling

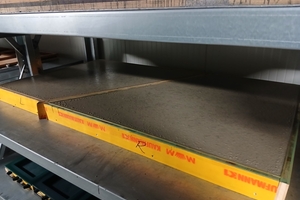

The filled molds are retrieved by an automatic stacker crane to be placed in the curing area for 24 hours. Moving on rails, the stacker crane is equipped with a pair of telescopic forks to place/remove the trays in/from the racks, and to present or retrieve them at the production and demolding stations.

Supplied and assembled by Rotho, the curing area can accommodate up to 110 mold support trays measuring 2,500 x 1,600 mm, arranged on ten racks of eleven levels each. Insulated, they are equipped with a ventilation system to homogenize temperature and humidity.

The stacker crane is controlled by a management interface that provides the reference number of each tray per location, as well as the date and time of concrete filling.

Working stations: ergonomic and convenient

The entire production line has been designed to make daily life easier for operators, enabling them to work in a comfortable and safe environment, with work position at ground level, no obstacles on the floor, light safety barriers and no manual handling of heavy loads.

So, after demolding, they can move freely around the trays and work in complete safety to clean and oil the molds and place the reinforcements in them, while articulated jibs equipped with suction pad grippers handle the demolded concrete products for palletizing.

Commissioned in July 2024, the production line, fully designed to meet the customer‘s manufacturing requirements, provides outstanding production rates in a comfortable and safe working environment.

Quadra’s ability to design coherent, scalable solution, the meticulous preparation of the work on customer site in advance, the effective coordination of the teams involved in the project, and the delivery of equipment which had been fully assembled and tested in the workshops, all contributed to ensuring that the customer’s specifications were met and a smooth start-up at the customer‘s premises.

With this new equipment, the French manufacturer reaffirms its position as a preferred partner for the design and development of customized solutions.

CONTACT

Quadra

40, route de Findrol

74130 Contamine-sur-Arve/France

+33 4 50 03 92 21