Stabils – straight steel fiber for efficient structural concrete elements

With its straight and high-strength Stabils steel fiber, Bilstein Group, worldwide leading company for cold-rolled special steels, is setting a new standard for efficient concrete reinforcement and for CO2-reduced precast elements. The core business of Bilstein Steel Fiber GmbH , located in Hagen, Germany, is not only the production, but also the marketing and the offer of services for all aspects of the innovative Stabils steel fiber.

Stabils steel fiber is the result of competence developed by the Bilstein Group in the steel sector over the course of 112 years. The focus lies on satisfying the demanding needs of its customers, maximum product quality and greatest possible sustainability.

The Bilstein Group is an internationally active supplier of premium cold-strip solutions. Application of the most advanced innovative technologies leads to ever new approaches. The possibilities of collaboration in a large network make the Bilstein Group one of the strongest international partners for cold-rolled strip applications.

Optimization of structural concrete elements

The choice of reinforcement has a major influence on the quality, loadbearing capacity and durability of a construction element. Ductility and crack restriction are critically influenced. Steel-fiber reinforcement, compared to conventional reinforcing steel, offers the following advantages:

Durable precast elements with improved CO2 footprint owing to more equal distribution of the fiber in the concrete element,

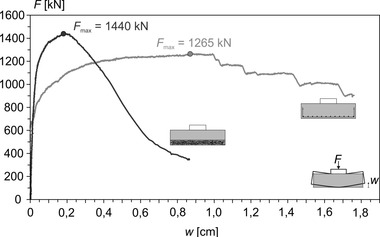

Outstanding post-cracking strength as a result of low-fiber batching,

Increase in durability and sustainability of concrete elements,

Lengthening of the life cycle of concrete elements,

Lower costs and practical engineering advantages owing to good processability of the fresh concrete, time-savings due to easier planning and faster implementation, lower costs from reduced material requirements and personnel costs, enhanced safety due to reduced risk of injury, no balling even when using higher doses and best pumpability.

Cost-efficient, secure and durable reinforcement for precast elements as a result of simple and precise batching as well as higher productivity.

Stabils steel fibers are also highly cost-effective. Less conventional reinforcing steel and less storage is required. Higher quality is achieved with less work, and less reinforcing steel guarantees a win-win situation. A standardized product needs effective reinforcement.

Production of quality products must not come at the cost of productivity. This applies especially to precast elements. For reinforcement, precasters who want to offer their customers an efficient end-product with long serviceability rely on high-performance Stabils steel fibers from Bilstein Steel Fiber.

Effectivity of the Stabils fiber

Concrete manufactured with Stabils leads to minimization of cracking. Precast elements with steel fiber, moreover, can be manufactured more productively because the amount of conventional reinforcement is significantly reduced or altogether replaced.

Concrete has inherently low tensile strength and ductility. These properties can be improved by the addition of reinforcement. A range of standards and codes of practice regulates the addition of reinforcement worldwide with emphasis on the following:

Minimization and restriction of cracking

Improvement of ductility

Enhancement of structural safety and serviceability.

Stabils service package

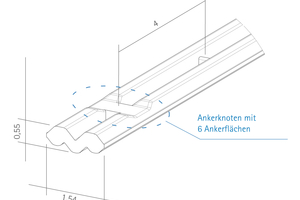

With Stabils steel fibers, forces are transmitted by sliding form-fit between fiber and concrete across the entire extraction process. The high ductility of Stabils steel fibers paired with significant tensile strength enables extremely great resistance to extraction without tearing.

Stabils steel fibers offer solutions to conventional reinforcement due to the special combination of a formed anchor knot and a high-strength material of extreme tensile strength.

The anchor knots of Stabils steel fiber are non-deformable and ensure optimal anchorage, with the result that the fibers remain firmly in the concrete.

An additional service provided by Bilstein Fiber is, if required, technological concrete consultation, support from initial testing to implementation, production to implementation at the construction site as well as solution approaches for assessing optimization of concrete elements. In collaboration with external specialized experts, moreover, optimization of construction elements through structural design, preparation of verifications of structural analyses, evaluation of cost-effectiveness and eco-balance as well as research projects with noted universities and higher-education institutions in Germany and abroad.

Sustainability of the products optimized

Recently, Dr.-Ing. Thomas Kranzler (Managing Director of the Syspro Gruppe Betonbauteile) and Dipl.-Ing. (FH) Silvio Schade (Editor-in-Chief of BFT International) visited Bilstein Steel Fiber GmbH in Hagen.

Jörg von Prondzinski, Managing Director at Bilstein, took his guests on a tour through production and explained in conclusion: “Thanks to our many years of competence in material and process engineering, we are able to adapt Stabils steel fiber to concrete application properties: e.g.,with regard to the fiber length, execution of anchor knots and adaptation of strength and elongation to the respective application. For years, we have aimed at optimizing the sustainability of products. An additional significant step along this path is participation in the H2 Green Steel Consortium. This group is in the process of building a steel plant with innovative technology in Sweden, by which the CO2 footprint of the material can be lowered by up to 90 %. And, not least, we continuously optimize the fibers and test them in actual production environments with allied partners such as Holcim Betonfertigteile in Neermoor, Germany.” (formerly Vetra, see also report in BFT 08-2024, ed.)

CONTACT

Bilstein Steel Fiber GmbH

Im Weinhof 36

58119 Hagen/Germany

+49 2334 82 1920