Stabils – The new generation of straight steel fibers

With the straight, high-strength Stabils steel fiber, the Bilstein Group, a global leader in cold-rolled special steels, is setting a new standard for efficient concrete reinforcement and low-carbon precast concrete elements. The core business of Bilstein Steel Fiber GmbH (a member of the Bilstein Group) includes not only production but also marketing and a range of services offered in relation to the innovative Stabils steel fiber.

The Bilstein Group employs a workforce of 1,400 at seven locations in five countries, generating an annual turnover of approx. 700 million euros. With an annual tonnage of over 500,000 tons, the company supplies around 1,200 customers worldwide.

The choice of reinforcement has a major influence on the quality, load-bearing capacity and durability of a concrete component, as well as on ductility and the limitation of cracks. Concrete produced with Stabils steel fibers effectively limits the crack width. In addition, Stabils steel fibers can increase the productivity of precast producers, since conventional reinforcement is greatly reduced or even replaced completely.

Mode of action of the Stabils fiber

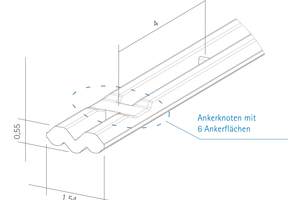

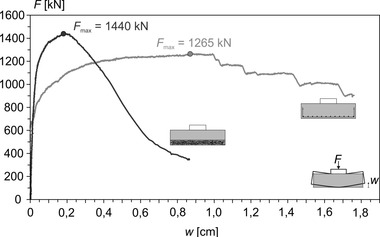

With the Stabils steel fiber, force transmission is achieved by means of positive locking between the steel fiber and the concrete over the entire pull-out process. Combining high expansion capacity with exceptionally high tensile strength, the Stabils steel fiber enables high pull-out resistance without tearing.

Compared to conventional reinforcement, Stabils steel fibers offer solutions based on the unique combination of a shaped anchor node and high-strength material with extremely high tensile strength.

The anchor nodes of Stabils steel fibers are resistant to deformation and ensure optimum anchorage so that the fibers are firmly retained in the concrete.

Durable precast concrete elements with improved carbon footprint at low cost

Stabils ensures even distribution of the fibers in the concrete component, excellent post-cracking strength with lower fiber dosage, as well increased component durability and sustainability, thus extending the lifecycle of the concrete component.

Further advantages include good fresh concrete workability, time savings due to easier planning and faster execution, a reduction in costs due to lower material requirements and labor costs, as well as increased safety due to a reduced risk of injury. The concrete has better pumpability and fiber balling is avoided even at higher dosages.

New quality in concrete reinforcement

Stabils provides impressive proof that advanced technology makes a big difference. This technology increases efficiency and cuts costs.

The unique design and geometry of the Stabils steel fiber offers an unprecedented level of anchorage, tensile strength and ductility, guaranteeing maximum performance, according to the supplier.

CONTACT

Bilstein Steel Fiber GmbH

Im Weinhof 36

58119 Hagen/Germany

+49 2334 82 1920