Standardized, cost-efficient pigment metering system for the concrete industry: Granumat Compact

In the concrete industry, the requirements on pigment dosing vary depending on the production scale. While large-scale industrial manufacturing facilities often require customized high-performance systems, there is an increasing demand for standardized, cost-effective solutions for smaller and medium-sized production lines.

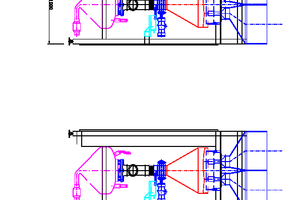

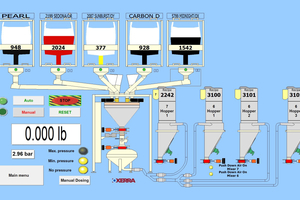

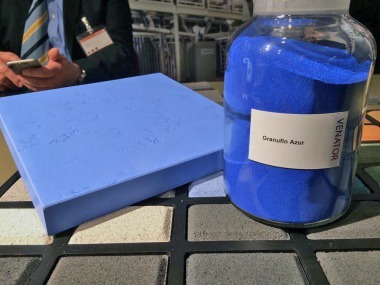

With the Granumat Compact, Oxerra expands its portfolio of metering systems with a standardized system based on the tried and tested Granumat technology, but was especially optimized for applications with a moderate need of pigments. The new version allows automated, gravimetric metering of pigments at low investment costs, without compromising in metering accuracy, process reliability or availability of the system.

Standardization as an economic advantage

While classic Granumat systems are designed for customer-specific adjustments, the Granumat Compact provides a standardized alternative for production environments, where precise pigment dosing is required, however, without the need of very high throughput capacities.

The use of pre-configured modular units results in several economical and technical advantages:

Reduced procurement costs owing to simplified, standardized design;

Minimized installation times owing to a modular structure;

Established gravimetric technology for high metering accuracy;

Fast commissioning for reducing production downtimes.

The standardization of the components allows a consistent process quality, reduces sources of error and makes maintenance and availability of spare parts easier.

Process technology and metering accuracy

Like all Granumat systems, the Granumat Compact is as well based on gravimetric weighing technology so as to guarantee a high degree of metering precision. A measuring precision of +/- 25 g minimizes color deviations, with ensuring a consistent color quality during long production cycles.

The pneumatic pigment conveyance enables a flexible installation of the system. Conveying routes of up to 100 m between metering system and mixer can be realized without a significant loss of performance. This technology provides for flexible installation options, dust-free pigment conveyance, which reduces material losses, improves safety at the workplace and minimizes cleaning effort.

Due to the compact design and the pre-configurated control system, the equipment can be incorporated into existing production lines at low integration effort.

System integration and control system

The standardized industrial Ethernet interface enables the direct connection to existing mixer control systems, without the need of complicated interface programming.

The independent control unit allows for uncomplicated handling of the system and remote maintenance, thus reducing plant downtimes and optimizing maintenance efforts. This contributes to a higher operational safety and a more efficient control of the process.

Areas of application

The Granumat Compact is suitable, in particular, for production environments with a moderate demand of pigments. Typical applications include:

concrete blocks (e.g., paving blocks, curbstones),

roof tiles,

precast concrete elements and

cast-in-situ concrete.

Due to the combination of standardized technology and high metering accuracy, the system provides an economic solution for concrete producers, being in need of precise and reproducible pigment dosing, however, not requiring individually adapted high-performance systems.

Conclusion

With the Granumat Compact, Oxerra responds to the changing requirements in the concrete industry and offers a cost-efficient metering system for smaller up to medium-sized production outputs.

Standardization of essential components allows a reduction of the investment and installation costs, without compromising the proven precision and process reliability of the Granumat technology.

For companies with a moderate need of pigments, the Granumat Compact is a sophisticated, economically reasonable alternative to a custom-made metering system.

CONTACT

Oxerra (Deutschland)

GmbH & Co. KG

Mühlstrasse 118

65396 Walluf/Germany

+49 6123 797-0