Strain-hardening cement-based composites (SHCC) in digital precast production

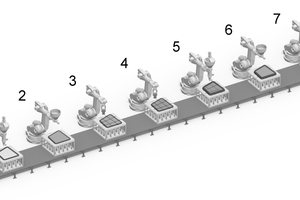

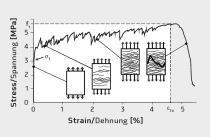

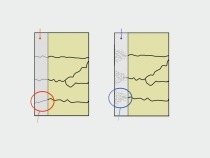

Strain-Hardening Cement-based Composites (SHCC) are characterized by their high strain capacity in tension. Due to their high tensile strength and an ultimate strain amounting to several percent, it is possible to completely dispense with conventional reinforcement for certain components. Among other benefits, this allows for the fully automated production of slender, material-efficient components exhibiting excellent mechanical properties for various load scenarios. The presentation will first give an overview of recent research findings on the composition, processing, and performance of SHCC under various load scenarios. The first case study covered in this contribution introduces the production of formwork panels at the precast plant using 3D printing, which are subsequently assembled on-site and used as integrated formwork for bridge piers. Using SHCC prevents damage to the formwork elements during transport and assembly and makes it possible to increase the hydrostatic pressure that can be absorbed during the placement of (self-compacting, SCC) fresh concrete. During the life cycle of the structure, the integrated formwork functions as a durable, highly ductile protective layer for the reinforced concrete core. The second case study refers to an innovative technology for the automated flow production of flat modules for the subsequent assembly of concrete gridshells. The modules comprise an edge zone and a filling. The edge zone is produced using a 3D printing process with SHCC, while the infill concrete is reinforced to the specified load-bearing capacity by a robotic free-form yarn laying system. The figure illustrates the individual steps of the production process. More detailed information is provided in [1].