Sustainable alternatives for wear treatment in concrete manufacturing

Concrete production businesses can now substantially reduce equipment downtime and related costs in the mixing and final production stages, thanks to the latest wearfacing technologie - therefore, concrete plants can both improve energy efficiency and reduce their CO2 footprint.

Concrete production businesses can now substantially reduce equipment downtime and related costs in the mixing and final production stages, thanks to the latest wearfacing technologies.

Martin Kirchgassner, Vice President and Chief Technology Officer of Castolin Eutectic, explains how this approach is integral to the company’s philosophy of “Pioneering Industrial Sustainability”, since if critical equipment functions optimally, it consumes less energy. Therefore, concrete plants can both improve energy efficiency and reduce their CO2 footprint.

By the very nature of their function and operation, concrete mixers and concrete-handling accessories are continually subjected to a highly erosive, abrasive and mobile mixture of cement, sand, aggregates and water. Its capacity for intensive wear, tear and damage is huge. Until it is replaced, a wearing component’s energy efficiency and operational performance may be lowered. This can lead to higher fuel consumption and in some cases higher material costs. It may also affect the quality of the concrete and increase the risk of its rejection.

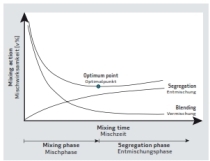

The industry is under increasing pressure to deliver an uninterrupted flow of ready-mix concrete, produced with a consistent, homogeneous quality and with ever faster mixing cycles. This is especially true for precast and prestressed concrete. The rising cost of energy and raw materials is another driver of efficiency, as is the growing demand for sustainable use of resources and reduction of carbon emissions.

Protecting equipment and components from wear helps toward meeting all these demands. It not only extends their life but maintains their original shape and dimensions, so they perform optimally and energy-efficiently. Wearfacing treatments can be applied during the equipment’s original manufacture and preparation. Alternatively, they can be added as part of a repair and restoration process which gives the component a second life and a better-protected future.

Concrete mixers

To understand the role of wear protection in concrete mixing, it is useful to first look at the anatomy and functioning of today’s concrete mixers. Fundamentally, they have a drum or pan in which the ingredients of concrete are stirred and homogenised with the aid of mixing tools. These consist of mixing arms to which are attached paddles for mixing and scrapers to stop the concrete from sticking to the drum or pan’s surface.

The arms are mounted on a rotating shaft which produces the necessary movement for stirring. More rarely, there are mixers in which the pan, rather than the mixing tools, revolves around a vertical axis. In older-style concrete mixers it was common for the drum to rotate around a horizontal axis, with the effect of mixing the contents by lifting and dropping them.

Concrete mixers can be divided into horizontal axis mixers (otherwise known as horizontal shaft or horizontal drive) and vertical axis/shaft/drive mixers. Within these, there are further divisions.

Most horizontal shaft mixers have two shafts, although single-shaft versions can be found occasionally. The twin-shaft machines offer high-intensity mixing with short cycles. They are typically used for high-strength, roller-compacted and self-consolidating concrete. Batch sizes tend to be between 2 and 6 cubic metres.

Vertical shaft mixers can be divided into pan types (sometimes known as ring-pan or turbine mixers) and planetary types (also known as counter-current mixers). Both kinds mix quickly and efficiently and are well suited to stiff as well as loose mixtures. The benefits of these machines include easy cleaning between batches. One of their differences from horizontal shaft mixers is that they discharge concrete via an opening in the bottom of the pan, rather than by pouring it from the top of a tilted drum.

Typical vertical shaft mixer applications include precast and prestressed concrete. The more efficient mixing action of the planetary types adds an advantage when consistency is most critical – in coloured and self-consolidating concrete mixes, for example. Batch size for vertical shaft mixers is normally small – between 0.75 and 3 cubic metres – and they are often used where multiple discharge points are needed.

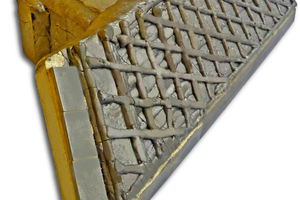

Mixer liners

Development of concrete mixer shielding is an area in which Castolin Eutectic has many years of expertise. An obvious place to start is by covering the inner surface of the mixer’s pan or drum with a protective lining.

For this, Castolin Eutectic has developed Castodur Diamond Plates (CDP®). These can be easily cut, shaped and fitted to protect any surface in any mixer design. In tests, CDP plates have been shown to give up to five times longer service life when compared with previous solutions. Those include heat-treated steel, polyurethane and cast iron.

CDP provides high protection while concrete is being mixed and also, importantly, during cleaning and maintenance. In addition, the plates are highly resistant to chipping. Other advantages include their low weight, which makes mixer transport easier.

CDP’s composite structure is made by arc-welding, vacuum-fusing or laser-powder-coating abrasion-erosion-resistant alloys onto an easily weldable steel plate. A highly controlled, high-tech production process, based on advanced material science, ensures premium quality and consistent properties across the entire surface.

The hardness of the material is typically two or three times higher than that of the most abrasive media used in industrial processes. Its durability owes much to the presence of ultra-hard phases – with a hardness value (HV) of 1,500 to 3,000 – anchored in a robust matrix.

CDP plates are available with different alloys and thicknesses, designed for specific wear scenarios. The three main categories are CDP Welded Plates, CDP Powder Plates and Laser Cladded Plates.

The plates provide an effective way of protecting both small and large surfaces. Retrofitting them is straightforward, with attachment by screws, rivets or spot welding. They are simple to cut to any shape, using standard methods such as plasma arc, water jet or laser, and are also easy to join. Alternatively, Castolin Eutectic can supply CDP panels pre-cut and formed to the mixer’s specifications.

Precise dimensions for the plates can be measured on site by Castolin Eutectic specialist engineers or taken from templates. A 3D measuring arm may be used to ensure accuracy. The engineers will return every six to nine months to check for wear and to plan for possible changes at the next liner replacement. To maintain the best possible fit and function, given that mixers change shape over their life, new measurements should be taken each time.

Mixing tools

The mixing arms, paddles and scrapers in a concrete mixer are all considered to be replaceable parts. Also present in some are arm protectors, designed as an additional protective measure for vulnerable surfaces on the arms.

Castolin Eutectic’s wear-resistant solution for paddle, scraper and arm protector surfaces is Castodur Diamond Carbide (CDC®). Components protected by CDC’s complex coating structure last up to six times longer than parts dependent on previous resistant technologies.

In tests comparing the durability of CDC-coated parts with that of mono-material replacement parts made from alternative hard materials, their life expectancy was six times better than standard hardened plates, four times better than polyurethane and three times better than Ni-Hard® cast iron.

The CDC coating is created using CDP plates, whose composition and properties have already been described above in relation to mixer liners. For extra wearfacing protection, tungsten carbide – with a hardness of 2,500 HV – is applied to the leading edges. The carbides have been specially chosen for resistance to impacts during mixer maintenance operations.

Individual parts can be repaired again and again using the same wear-resistant alloy in electrode form. Like CDP plates, CDC coatings are available with different alloys and thicknesses designed to combat specific types of wear. The full catalogue contains around 300 CDC parts, each of which is supplied with fixing systems. They are compatible with more than 20 mixer brands.

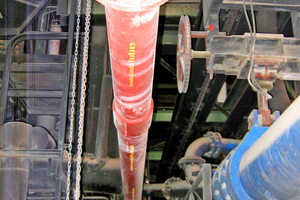

Pipework

Concrete ingredients and the resulting mixed concrete may be transported via a system of rigid, small-diameter pipes, with elbows for changes in direction. Their inner surface is, unsurprisingly, prone to erosive and abrasive wear.

The answer from Castolin Eutectic is CastoTubes. These easy-to-weld mild steel tubes are protected internally by a welded coating of TeroMatec 4666 alloy, which is extremely wear-resistant. It gives the same level of wear resistance as Castolin Eutectic’s CDP 4666 plates but avoids the difficulty and expense of having to form plates into tubes.

Inner diameters from 82 to 300 mm are available. Spiral welding has been used to minimise any distortion. The tubes are seamless, with perfectly round cross-sections and no linear weld joints. They are highly cost-effective, light to handle, and quick and easy to connect.

In laboratory abrasion wear tests, the resistance of CastoTubes has proved superior to that of mild steel, heat-treated, 400HB hardened plate and chrome carbide tube products.

Like CDP, TeroMatec 4666 is typically two or three times harder than the most abrasive industrial media, thanks to a structure with multiple ultra-hard phases anchored in a tough matrix. Importantly, controlled cooling during manufacture results in dense dispersal and strong orientation of those hard phases. This gives much greater wear resistance compared to conventional weld coatings.

Along with standard CastoTubes, which resist abrasion and erosion up to 500⁰C, Castolin Eutectic can supply alternative alloys and base tube compositions on request. These may be needed to cope with high-temperature erosion, for instance.

Tube sections up to a maximum of 3 metres are available. They can be joined by simple welding or mechanical methods. The tubes can be delivered with integral or slip-on flanges, or with other flange joint types or custom connections on request. Within the wide range of internal diameters, the precise wearfacing thickness can be varied to achieve a closely mating joint and avoid turbulent flow.

CastoTubes arrive ready to assemble, with Y-joints and elbows in place if required. Castolin Eutectic fabricates elbows in advance by cutting the tubes into wedges and reassembling them according to the customer’s specified pipework geometry.

Final production

Castolin Eutectic also offers a range of wear-resistant solutions for various equipment involved in forming concrete into the required shapes for construction.

A good example is in the extruder elements for hollow-core slab production. As well as increasing the service life of the forming sleeves by up to eight times, Castolin Eutectic’s technology maintains their original geometry. Any shrinkage of these sleeves through wear decreases the size of the air cavity, which increases the amount of concrete used and the weight of the final product.

Other Castolin Eutectic solutions can be found in concrete spreaders. These extend component service life by four to six times compared to 400HB steel in floor spreading equipment and by two to three times compared to CrC hard alloys in auger-type applications. In the case of drawer table plates, Castolin Eutectic can double or quadruple service life compared to heat-treated steel components.

Whatever the wear-related challenge in concrete mixing, transport or final production, Castolin Eutectic has the answer. A network of 700 technicians and specialists is ready to provide on-site wear detection, analysis and advice, before recommending the ideal solution. Repairs and wear protection can be applied either at the customer’s own site or in Castolin Eutectic’s specialized workshops.