Sustainable coastline protection with non-

interlocking concrete slab revetments

The consequences of climate change are also evident in Europe – one example is the rise of water levels in the North and Baltic Seas. Protection of the coastline plays therefore an important role. Non-interlocking concrete block revetments are therefore the ideal alternative for use in and near the water.

The impact of climate change is also evident in Europe. In addition to summer droughts and torrential rain and flooding, water levels in the North and Baltic Seas are rising as well. Protection of the coastline therefore plays an important role when combating climate change and its accompanying effects. In building and upgrading dikes, sustainable revetments – as sustainable surfaces for dikes and embankments are called – are therefore essential.

Concrete, owing to its material properties, is the ideal material for use in and near the water. It is maintenance-free, durable and has high compressive strength. Its constituent materials are moreover extracted locally or regionally, thus eliminating long transport routes and dependence on raw material imports.

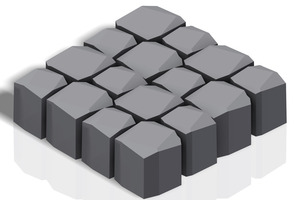

Holcim basalt-clay concrete columns and basalt-clay Quattroblocks

A particularly innovative solution in coastline protection and stabilization of embankments is non-interlockingconcrete blocks: such as the basalt-clay Quattroblock and basalt-clay concrete columns from Holcim. The original form of the concrete blocks corresponds to the form of natural basalt columns, similarly used in many dike constructions for centuries. The basalt-clay Quattroblock is the further development of the individual column. The Quattroblock consists of four interconnected concrete columns measuring approx. 55 x 55 cm. With a joint area of approx. 11 %, this results in an area of 1.18 m².

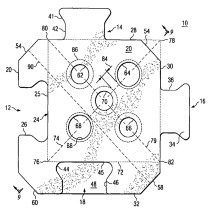

The block height can be chosen in steps of 20 to 55 cm, in increments of 5 cm, to accommodate the loads to be resisted. In design and construction, these fine increments in block heights enable selective inclusion of so-called break-up blocks that project from the laying cluster. This type of installation, as illustrated in the figure, results in a braking effect that markedly reduces the cumulative energy of the waves onto the revetment.

Simple and fast laying

Basalt-clay Quattroblocks, as opposed to other concrete blocks, are not delivered on pallets to the construction site. The block packages are loaded in such a way that further processing with a standard gripping tool on a mobile excavator is sufficient. This results in an enormously high installation rate that enables fast construction process. That is of special advantage for carrying out small repair measures in areas influenced by the tide. In contrast to rubble-fill revetments, the concrete blocks laid on the laying course are immediately loadbearing. Freshly laid rubble revetments should be left to lie up to four weeks before beginning the second step of work – cleaning, then subsequent joining with cement mortar.

Non-interlocking revetments, in addition to the fast construction process, also provide more security against settlement, since revetments of loosely placed blocks stabilized with mortar often develop cracks and voids between blocks and joining mortar soon after the construction phase. These damages, when acted upon by waves or subjected to frost, can quickly lead to voids and leakage in the revetment.

Innovative and sustainable

Non-interlocking concrete block revetments are an especially sustainable alternative to conventional revetments. Transport is reduced and the impact on the environment is diminished due to local availability and production of the constituent materials. When CO2-reduced cement is used in addition, the CO2 footprint of the revetment is reduced to such an extent that this construction method is especially effective from a sustainability viewpoint.

Since cement production without CO2 is currently not yet possible, a large portion of the clinker is substituted by other interground additions with a lower CO2 footprint. Here, an acceptable compromise among strength, strength development and durability is necessary. Use of CEM III cements in production of basalt-clay products, can save considerable amounts of CO2.

Reliable coastline protection that pays off

Frequently, only the initial investment is considered for projects. But rapid construction processes and especially durable and maintenance-free construction are rather seldom taken into account – at the disadvantage of innovative construction methods. All too often, supposedly favorable one-off investments, in the course of service, turn out to be cost traps. Numerous tests in wave tunnels or in practice have proved an especially high stability and a low failure probability for this new technique. This reduces frequency and amount of work required for operation, as well as of repair work. This makes coastline protection with non-interlocking revetments of concrete blocks more reliable and at the same time more cost-efficient.

Projects in Büsum and on the Eiderdamm in Germany

Because of these numerous advantages, the authorities for coastline protection, national parks and marine protection – Schleswig-Holstein (LKN.SH) “Landesbetrieb für Küstenschutz, Nationalpark und Meeresschutz - Schleswig-Holstein (LKN.SH)” has already decided on the use of basalt-clay Quattroblocks.

For rehabilitation of the revetment on the southern beach of the seaside resort Büsum in the district of Dithmarschen, Germany, a total of 1200 m² of basalt-clay Quattroblocks were laid on the seaside and on the harbor side in June 2021. LKN.SH and the general construction company were convinced of the performance capability and economic efficiency. Due to the influence of the tide, installation had to take place quickly and in small construction sections that were required to bear loads immediately. In one work shift, it was necessary to remove the damaged existing revetment, lay the geotextile, install a laying course and install the basalt-clay Quattroblock, using a simple gripping tool on a mobile excavator.

Based on this positive experience, LKN.SH has now decided to use basalt-clay Quattroblock as well for the rehabilitation and upgrading of Eiderdamm-North.

The Eiderdamm-North dike was constructed in 1973 as an asphalt dike. Now, in addition to constructional defects – such as cracks in the asphalt surfacing, sand discharge from the core of the dike and settlements – the profile of the dike no longer meets current requirements. The objective of the project is to rehabilitate and/or adapt the dike in accordance with the safety and design concepts set forth in the General Coastal Protection stipulations of the German state of Schleswig-Holstein.

The dike to be upgraded has a total length of 3.85 km, onto which from 2023 to 2026 a total of 130,000 m² basalt-clay Quattroblock will be installed. For a classic climate profile with clay and backfill soil, neither sufficient material nor construction space is available for a classic solution, since it would extend the width of the dike base by 30 m. The dike toe will be retained and the upper revetment will be provided with so-called break-up blocks that will reduce wave impact. For this purpose, concrete blocks 20 and 35 cm high will be placed in a row. This construction method with so-called break-up blocks enables carrying out technical optimization without widening the dike. Apart from the choosing a sustainable construction method, using concrete block revetment, the LKN.SH has decided to reutilize the old asphalt of the dike embankments. For this purpose, the asphalt will be removed, reconditioned on location and again completely reinstalled as understructure in the dike body. This eliminates expensive transport and high landfill costs.

With this method using selected construction method with basalt-clay Quattroblocks, and with reutilization as much as possible of the existing construction materials, the LKN.SH has chosen an especially sustainable variety of conventional revetment.