SW Umwelttechnik expands production site in Romania

The product range of SW Umwelttechnik encompasses 112 years of experience in the development and production of precast concrete elements for civil engineering, transport, building and residential construction. In 2022, the precast concrete market registered an increase of 21% compared to the previous year and a quantitative decrease of approximately 2%, according to specialized studies. In this context, thanks to the large product portfolio, the increase in production capacities and the market share, the manufacturer of precast concrete elements SW Umwelttechnik registered a growth of 38%, reaching, in 2022, a turnover of 189.4 million of Lei. For 2023, the company‘s estimates show an increase in turnover, in the context of the further development of production capacities. Currently, SW Umwelttechnik owns three production units in Romania, in Ortisoara (near Timişoara), Izvoru (near Bucharest) and Cristeşti (near Iaşi), with a total production capacity of over 350.000 tons per year.

In addition to the usual prefabs produced (columns, main and secondary beams and prefabricated walls) the company wants to strengthen its presence in the field of precast concrete elements intended for the construction of roads and bridges. Thus, SW Umwelttechnik have completed their entire range of products intended for bridges and walkways; they also completed, within the factory in Izvoru, the project to expand the production of bridge beams, with openings of precast concrete beams of up to 42 meters, as well as prefabricated slabs intended for bridge constructions.

Growth potential in Romania confirmed

„Production in Cristeşti has been fully utilized in recent years, both in terms of water protection and infrastructure,“ says Klaus Einfalt, member of the board of SW Umwelttechnik.

“We are pleased about the expansion of our plant and the associated significant increase in our production capacities. With the expanded facilities, we can guarantee even better support for customers in the region and shorten transport routes. Fortunately, the new capacities are already almost fully utilized.“ Einfalt continues.

The new machines and systems will be used for prefabricated structural parts. Among other things, a new concrete tower batching plant with two mixers with a capacity of two cubic meters each was installed. The existing parts of the hall can thus also be used for the manufacture of products in the field of civil engineering. In total, the newly installed facilities and buildings reflect a total value of around EUR 15 million.

„With this expansion, we are demonstrating the growth potential in Romania and also creating numerous jobs in the region. All in all, we also underline the importance of Austrian companies in Romania and look forward to the implementation of numerous projects that we can cover with products from our broad portfolio,“ concludes Klaus Einfalt.

Heart of the new factory

The new equipment for concrete production and distribution was developed during an intense stage of engineering, for the challenge of combining the desired vertical layout for the batch plant and an efficient and automatic system for the distribution of concrete, all integrated in the factory and site layout with strict inputs concerning the room available and traffic pattern.

The developing work was assigned to MCT Italy, thanks to their long-term expertise both in tower batch plant solutions and automatic concrete distribution systems. “The Cristeşti project had a large amount of challenges, from engineering to management, which required a strong partner”, says Gabriel Neculae, Managing Director of SW Umwelttechnik Romania “and we needed to count on the experience and organization of a trusted supplier as MCT proved to be in the previous projects within the SW Umwelttechnik group”. The cooperation between MCT and SW engineering departments ensured a smooth project development, easily working out the high standards required, also within the project’s investment framework.

The tower batching plant develops on a 30m high configuration to minimize the impact on the footprint and includes an aggregates loading system, also successfully adopted on projects developed by MCT for the SW Umwelttechnik in Hungary, as well as underground primary hopper and buckets elevator, featuring an automatic dispensing conveyor on the top of the tower.

The overhead aggregates storage, composed of 6 compartments and a capacity of almost 700 tons, is entirely developed with modular galvanized panels to ensure a quick and safe installation. All the compartments can feed both mixers through a compact aggregates dosing scale with diverter system to feed holding hoppers integrated above the mixers. This configuration allows a very fast and accurate concrete production.

Cement storage is also designed to be as compact as possible with 4 silos of 100 tons capacity each and smart and compact screw conveyors distribution to be able to feed all production lines with all powders. Also, the distributing screws are all installed on a maintenance platform for the ease of service and the safest operations. These latter topics are a must on MCT designed plants, where comfortable room on platforms, ease of access to all machines and safety are the most important inputs for the design and development of plant solutions.

This particularly reflects in the well-organized mixers platform, where the two 3000/2000 planetary mixers with all the related accessories are compactly arranged to minimize the waste of spaces and optimize the maintenance and operation friendliness.

Among the design challenges, the plant was developed to feed one line of flying buckets in the current phase 1, feeding 2 production bays, with potential development for a second future line to feed more production bays. Within this layout, the second line is currently used to include a concrete holding hopper to feed ready-mix trucks from both mixers. This solution is of great value for SW Umwelttechnik for feeding other uses throughout the large production facility, other than to pour concrete for their own slab development in the cleanest and simplest way.

A real milestone

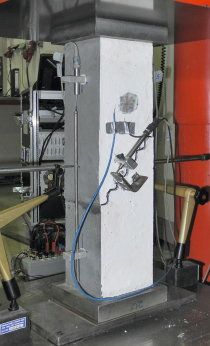

The fast concrete distribution system, masterpiece of MCT solutions, features 2 sets of flying buckets type AV Aerovan and a casting machine type BR, each dedicated to one production bay. This automatic concrete feeding ensures the fastest pouring phase for the prefabricated elements bays, allowing more time for natural curing of the products, being paramount to achieve the highest quality standards required by SW Umwelttechnik.

The detachable casting machines type BR also optimize the use of the overhead cranes, being installed on the dedicated cranes only when pouring, and being parked on the other phases of the production to allow the usual lifting operations with the overhead cranes, thus not requiring a dedicated crane tool to operate the pouring machines. The flexible buckets installed can properly handle SCC and all types of concrete for the production of columns, beams and panels, also featuring a rotating bucket with hydraulic gate to smoothly manage the pour on the molds in different directions and discharge flow rates.

The new factory was successfully inaugurated on 30th of June, at the presence of SW Umwelttechnik management, local authorities, and a delegation from MCT, including Eng. Alessandro DiCesare, VP of Business Development, who commented: “We are extremely proud to be a key supplier of SW Umwelttechnik, which is a great team to work with and a trusted partner helping us develop new solutions and work on highest standards. The continued partnership with this group, among others in Eastern Europe, allows us to work projects out efficiently and successfully, since we are very familiar with the own challenges and requirements of such companies and markets in general, maximizing the results of our efforts to provide the best tools for our customers.” The important referrals and market shares in Eastern Europe confirm the successful approach of MCT in these countries and the SW Umwelttechnik Cristeşti project represents a real milestone, setting, as a complete factory, the standards in this area.

CONTACT

SW Umwelttechnik România S.R.L.

Str. Zăvoiului Nr. 1, Sat Izvoru, Jud. Giurgiu

087253 Izvoru/Romania

+40 246 207050

MCT Italy Srl

Via Perugia 105

06084 Bettona/Italy

+39 0759 8855 1