The development of climate-friendly materials forwarded

Reductions of more than two-thirds in CO2 emissions with consistently high quality: researchers at Fraunhofer Institute for Building Physics (IBP) are adjusting numerous key factors to make the future production of the familiar construction material as climate-neutral as possible. They will show their solutions at Messe BAU 2025 from 13 to 17 January in Munich.

What would the perfect concrete look like? Scientists at Fraunhofer IBP are asking themselves this question: it should be versatile in use and sustainable, manufactured with local resources, if possible, recyclable and resistant and, in addition, produced with low CO2 levels. Researchers are working on many different solutions that have the potential to decisively change the construction industry.

In search of the perfect concrete

A central lever of the researchers: they substitute various constituents of the concrete with pyrocarbon. For their production, they heat plant residues or other organic substances, such as methane, in an atmosphere that is low in oxygen. In the process, up to 40 % of the carbon contained in the plants is stored as solid substance in the form of pyrocarbon. By their integration, it is calculated that more carbon dioxide is bound than is emitted during production.

The researchers not only modified the pyrocarbon to make it suitable for inclusion in concrete precisely as required. In addition, they developed a process for granulating the additions to concrete. With the finely divided materials < 2 mm, they replace the sand in the concrete. This makes it not only more climate-friendly, but significantly lighter as well: which, moreover, saves transport costs.

“When we employ one part of pyrocarbon, it is possible to reduce approx. three parts of CO2 in total production. This brings us very close to climate-neutral concrete of a quality that is in no way inferior to the conventional variant,” explains Dr. Volker Thome, Head of the Department Inorganic Materials and Construction Material Recycling at Fraunhofer IBP. To further improve the CO2 balance of the concrete, and to conserve natural resources, researchers also use so-called biogenic lime. For its manufacture, carbon dioxide is likewise withdrawn from the atmosphere and bound in the lime as a solid.

Finding the right clay

Another starting point for the researchers in their search for reducing CO2 emissions is achieved by less clinker content in the cement. In view of the diminishing availability of conventional cement substitutes and additions to concrete – such as granulated blast-furnace slags and fly-ash – researchers at Fraunhofer IBP investigated clay as suitable alternative material: i.e., one which remains locally available in the required quantities. In Germany, various types of clay exist that, thermally or mechano-chemically activated, can be added to the cement as additive to concrete.

In the „LOCALAY“ project, a group of researchers at Fraunhofer IBP investigated, based on various clay types, formulations for use in mass construction material with the use of low-level CO2, reduced cement clinker and binders without cement. Towards this objective, the researchers identified and analyzed clay deposits. They also developed a reactivity test with which they can quickly determine how specific clay types, depending on their intended use, are best activated and tested for workability and durability.

Such types of clay exist in large quantities in Germany, primarily in excavated soil. Their recovery, amounting to 125 million tons annually, represents the largest share of mineral flow in the country. In order to exploit this potential, Fraunhofer researchers are accordingly extending their competence in soil analysis – from processing the excavated soil for separation of clay fraction extending to utilization of extremely fine clay types in filter cakes, such as are formed, for example, when washing vegetables.

Moving an antique original into the modern era

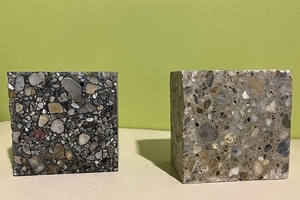

In the search for the future of concrete, it is worth taking a look into the past. The Roman concretes used in antiquity, indeed, fulfilled all criteria of modern sustainable construction materials. They contain no cement, consist of locally available resources such as volcanic ash, and are not only durable, but also resistant to many external influences. The basic formulation for them is unfortunately lost. In the „RICIMER“ project (Roman Inspired Cement Innovation by Multi-Analytical Enhanced Research), researchers of Fraunhofer IBP are investigating this Roman formulation, together with colleagues at the Max-Planck Institute for Solid State Research in Stuttgart. Their aim is to find the original formulations and to apply them to modern construction materials.

Volker Thome is convinced: “We are close to finally solving the mystery of the antique cementless formulations. We must now develop formulations on the basis of these results, according to the sustainable Roman model and by using waste-incineration and industrial ashes instead of the volcanic ashes used in in antiquity.”

Geopolymers – unlocking archaic knowledge for the future

Even concrete additions that make structures more sustainable are not phenomena originating in our modern age. Wonders of the ancient world, such as the Egyptian Pyramids, were presumably created with their aid. The fact is that so-called geopolymers or alkali-activated binders, depending on their composition, are corrosion-resistant, high-strength and non-flammable. For this reason, they are suitable for use in areas subjected to great chemical stress: e.g., for coating sewer channels. In Australia they are, due to their strength, already being used in constructing runways and buildings.

Whereas primary raw materials are needed for the manufacture of conventional construction materials, Fraunhofer IBP researchers use communal residual masses or industrial by-products such as fly-ashes and blast-furnace slags. “By now, we have gained extensive experience and can produce geopolymers for the respective utilization cases,” explained Thome.

At BAU 2025, the world’s leading trade fair for architecture, materials and systems in Munich, the researchers will show their solutions from 13 to 17 January. They will, among other examples, present climate-neutral pyrocarbon concrete, Roman concrete and a selection of geopolymers.

CONTACT

Fraunhofer-Institut für Bauphysik IBP

Fraunhoferstr. 10

83626 Valley/Germany

+49 8024 643-626