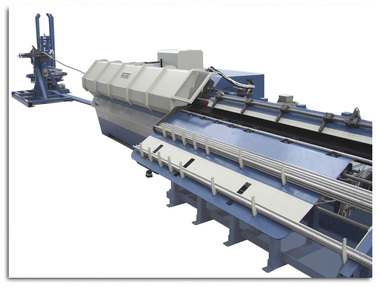

The Flexiline series – straightening quality meets flexibility

The Eurobend Flexiline rotor straighteners are delivered in different configurations with up to six 5G rotors with hyperbolic rollers. Each rotor is dedicated to a diameter. Diameters up to 25 mm are processed.

The latest 5G rotors ensure excellent straightening quality, better than 1/1000, without damaging the reinforcing steel ribs, even with high ductile material, such as reinforcing steel of ductility class “C” with diameters up to 25 mm. After processing, the material properties and the rib height are not affected.

All machines in the Flexiline series feature the patented Eurobend convergence guidance system for automatic diameter changes in less than three seconds, without mechanical moving parts. The rapid diameter change ensures the production of different rebar diameters, one after the other within the same batch, economically and without any loss of time. A flying shear used by all lines guarantees uninterrupted operation and minimization of material stress. The Flexiline straighteners are available in different configurations from three up to six lines.

The last coil piece is fed out in the production direction using the sophisticated last bar extraction unit (patent). The new wire can then be threaded directly into the machine using the powered prestraitening and wire guiding units. Adjustments of the rotor‘s hyperbolic rollers are not necessary. This eliminates the need for time-consuming wire insertion with butt welding units, especially at the large rebar diameters. The system saves over 100 working hours per year.

A robotic coil opening system enables easy and quick wire insertion into the machine. This system is particularly advantageous for large diameters of 20 and 25 mm.

All functions without manual adjustments

Two high-precision servo driven bending modules can be integrated to the Flexiline rotor straightening machines, with which the operator can straighten, cut and bend, all positions of the production plan one after the other.

This is the unique Syntheton series. With the Syntheton machines, the diameter change takes place automatically in less thaan 3 seconds and the bending tool change takes place in “0” time. All bending diameters are integrated in a retractable bending tool. A time-consuming tool change is no longer necessary. This system allows different bending radii on the same bar.

All functions run without the need for manual adjustments or operator intervention. The process is controlled by a computer with user-friendly Windows-based software.

The Flexiline and Syntheton machines exchange production data between the computer and the factory environment via software interface in various industrial formats (such as “BVBS”, “Unitechnik” and others).

CONTACT

Eurobend GmbH

Alexanderstr. 1

90547 Stein-Nuremberg/Germany

+49 911 9498980