The use of recycled crushed concrete sand as basis for alkali-activated concretes

This paper examines selected findings of a research project funded by DBU as part of which practice-oriented applications of alkali-activated binder systems based on recycled crushed concrete sand were investigated in respect of the production of concrete products.

The cement industry and concrete manufacturers together are appealed for reducing the consumption of resources as well as the carbon emissions related to the production of cement. This paper examines selected findings of a research project funded by DBU (German Federal Environmental Foundation) as part of which practice-oriented applications of alkali-activated binder systems based on recycled crushed concrete sand were investigated in respect of the production of concrete products.

1 Introduction

Owing to the positive developments in the field of renewable energy sources, there is, among others, a rapid decline in the accruing quantities of fly ash produced in hard coal-fired plants. In addition, in the last few years, there have been signs of a slight decline in the crude steel production which is the basis for the production of ground-granulated blast-furnace slag. As the entire quantities of hard coal fly ash and blast-furnace slag are already used in the cement and/or concrete industries today, it is imperative to provide the construction industry with alternatives to Portland- and fly ash-based cements as binder for concrete.

In the past just over 100 years of company history, the medium-sized, family-owned company – Rekers Betonwerk GmbH & Co KG based in Spelle – has developed to a powerful supplier of concrete products in Germany with more than 800 own employees working at four German locations today. During the concrete production in the different production segments an excess of fresh concrete as well as a certain amount of waste are unavoidable which are occurring as so-called production rejects. However, there is yet considerable potential for improvement when it comes to high-grade recycling of this waste as building material components. The fine fractions of the crushed concrete recyclate with grain fractions below 2 mm is hardly used at present. The potential for the production of new concrete products lying in these fractions is currently not utilized owing to a lack of knowledge in respect of the effect on the relevant properties of fresh and hardened concrete.

Against this background, the research project of Rekers Betonwerk GmbH with the collaboration of FH Münster University of Applied Sciences presented here was aiming at showing alternatives for the production of building materials based on concrete. More precisely, within the project, a concrete paving block was developed consisting of a clinker-free mortar component made of crushed concrete sand recycled from the production waste occurring at Rekers and a suitable metakaolin. As the cement clinker that is causing carbon emissions is completely substituted in this alternative concrete, the greenhouse potential should be minimized and natural resources should be conserved.

The object was to use the high portion of „stored“, gray energy in the residual concrete as holistically as possible, so that the fine fraction of a correspondingly crushed residual concrete can be re-used in the production as a binder component. This would further reduce the use of Portland cement and additives such as fly ash or blast-furnace slag for the production of new concrete products, while allowing for a high-grade utilization of concrete waste at the same time. The result is a significant improvement of the eco-balance of the production process of concrete components.

The research project was divided into several development steps (cf. Fig. 1) for achieving the goals set. In the following sections, selected areas of the research project are discussed more detailed.

2 Characterization of the basic materials

The material hereunder referred to as crushed concrete sand is structural concrete waste from the running production, being crushed to a grain size of 4 mm and then screened through 500 µm. The proportion of grain size < 100 µm amounted to 22 wt.-%. The used, much finer metakaolin has a fineness (d90) of 15 µm.

A summary of the material composition and the density of the used basic materials –crushed concrete sand, metakaolin and activator solution (sodium silicate solution) – is given in Tab. 1).

The distribution of elements shows a comparable SiO2 percentage for crushed concrete sand and metakaolin of 65 wt.-% and 55 wt.-% respectively. However, it must be taken into account that an amorphous constellation of the relevant element bonding (SiO2 and AI2O3) must exist to obtain the intended alkali activation of these materials [1]. It should also be noted that a not insignificant proportion of silicates in the crushed concrete sand exists in crystalline form because they originate from the aggregates (Rhine gravel). Therefore, reactive potential was assumed in the portion of the possibly not yet hydrated cement and/or in new reaction surfaces after breaking. In case of the thermally processed metakaolin, in contrast, there is a high portion of amorphous and thus reactive SiO2 and AI2O3 owing to the production process, which could be confirmed by means of x-ray diffraction analyses. Further details and research results can be found in the research report [2].

The sodium silicate solution featuring a molar water-glass module of 3.3 used as activator was set to modules between 1.7 and 2.0 by the purposeful addition of commercially available caustic soda scales. The water-glass module represents the mass ratio between the silicate constituents and the hydroxide constituents of the solution, thus having a relevant influence on the possible chemical processes in the alkali activation.

3 Development of alkali-activated mortars with a high content of crushed concrete sand

Against the background of the production process at Rekers, criteria and requirements were defined in accordance with Tab. 2 for the mortars to be developed. These included, apart from the criterion of workability, the compressive strength and flexural strength after 28 d in compliance with DIN EN 196-1 [3] and in accordance with DIN EN 1015-11 [4] respectively.

The required workability of the mortars was set by the ratio of activator solution to solids (crushed concrete sand + metakaolin) – referred to as „BMG“ hereunder – as well as by the water-glass module. Normal sand according to DIN EN 196-1 was used as aggregate [3]. An excerpt of the examined mortar compositions is given in Tab. 3 using the example of water-glass module 1.7. The gradation of the crushed concrete sand/metakaolin ratio, in steps of 25 wt.-%, remained unchanged for all water-glass modules from 1.7 to 2.0.

At a water-glass module of 1.7, all mixtures achieve a workability time of between 30 and 40 min. The workability time increased along with the increasing water-glass module, however, achieved acceptable values for practical applications at higher water-glass modules too.

By using a proportion of 100% of crushed concrete sand, it was possible to produce mortars being very well workable in the production of paving blocks, but compressive strengths after 28 d of max. 5.5 N/mm² were in a range not relevant in construction. A subsequent storage of the specimens in water revealed a nonexistent water resistance, why only a predominant water-glass binding capacity had to be assumed for these systems. Compressive strengths of up to 70 N/mm² after 7 d were already achieved with a metakaolin proportion of hundred percent as a function of the water-glass module. These mortars did not feature any water solubility.

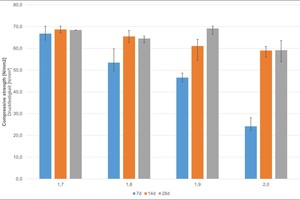

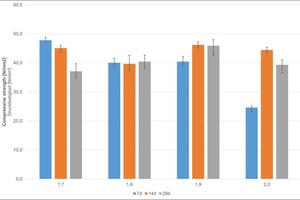

Owing to the objective of an as high as possible portion of crushed sand with fresh mortar properties being relevant in construction simultaneously, the mortars with a proportion of 75 % and/or 50 % of metakaolin proved to be purposeful. Fig. 2 and Fig. 3 show the determined compressive strengths of the respective metakaolin portions for the water-glass modules 1.7 to 2.0 exemplarily.

At a portion of 75 wt.-% of metakaolin the mortar specimens achieved compressive strengths between 60 and 70 N/mm² after 28 d, between 35 and 45 N/mm² were determined at a metakaolin content of 50 wt.-%. It must be noted that a noticeable strength loss was identified after 28 d at a water-glass module of 1.7 and a metakaolin content of 50 wt.-%. A concluding explanation for this phenomenon could not be found in the context of the test series.

The flexural strengths not shown here reliably achieved the requirements stipulated in Tab. 2 for all mortars shown. At a water-glass module of 1.7 and a metakaolin content of 75 wt.-%, for example, around 9 N/mm² were achieved and at 50 wt.-% metakaolin content about 6 N/mm².

4 Development of alkali-activated concretes with a high content of crushed concrete sand

To achieve the paving block prototypes specified as project goal shown in figure 1, concretes were developed based on the mortars developed, which should have an as high as possible content of crushed concrete sand, with featuring practice-oriented fresh and hardened concrete properties. For this reason, apart from the already developed mortars with crushed concrete sand/metakaolin ratios of 25/75 and 50/50, an additional mortar with a ratio of 40/60 was examined.

The mortars developed in advance were translated to the concrete scale by the addition of aggregates (GK) as an aggregate mixture with a grain size of 8 mm. Apart from the ratio of the activator solution (WGL) to BMG, the ratio of GK/(BMG+WGL) was varied as well. Both ratios had a direct influence on the workability as well as the fresh and hardened concrete properties of the concretes developed. The below-mentioned Tab. 4 states the selected parameters and their ranges, which were examined in comprehensive test series. In this connection, three concrete groups „1“ to „3“ have been formed, which were characterized by the ratio of crushed concrete sand to metakaolin.

Preliminary tests have shown that the best compromise between material properties and practical application in construction was reached at a water-glass module of 1.9. Therefore, this value was specified for the development of concrete.

In accordance with the mortar tests, the criteria and requirements for testing the concretes for paving blocks, which are stated in the following Tab. 5, were formulated on the basis of Rekers‘ production experience.

The consistency/haptics as an important criterion for the workability of a concrete mix design was described through so-called hand kneading test, cf. Fig. 3 on the right and on the left. The flowability, stickiness and wetness of the mixture were specified as evaluation criteria and compared to reference concretes from the production.

The left figure illustrates an example of bad cohesion of a concrete. Individual agglomerates are forming, which show an acceptable flowability, but not an optimum cohesion among each other. An example for a good cohesion of fresh concrete in a kneading test is given in the figure on the right. All mixtures, which could not fulfil the requirements on workability, were no longer taken into account for further investigations.

For investigating the green strength and hardened concrete properties, test cylinders with a diameter of 150 mm and a height of 300 mm were produced from the concretes with acceptable workability, and they were compacted by means of a self-developed method and demolded immediately, cf. [2].

Fig. 4, on the left, impressively shows that not every concrete featuring an acceptable workability in the kneading test also had a sufficient green strength. This applied to all test specimens of concrete group 2 with a metakaolin content of 50 wt.-%. For concrete groups 1 and 3 with higher metakaolin contents of 60 wt.-% and 75 wt.-%, dimensionally stable specimens were observed even after a long test period, cf. Fig. 4 on the right.

As in the evaluation of the consistency, the two varying ratios of WGL/BMG and GK/(BMG+WGL) had a significant influence on the green strength of the concrete as regards the cohesion after demolding.

Following the comprehensive investigations on the fresh concrete properties and on the green strength, the most promising concrete compositions were used to carry out tests on hardened concrete which revealed that not every concrete with a sufficient green strength also features sufficient hardened concrete properties.

5 Production of paving block prototypes and checking of the material characteristics

Hence, the concrete compositions complied in the following Tab. 6 could be identified as the most promising „candidates“ for the production of paving block prototypes. These are hereafter referred to as Concrete 1 and Concrete 3 in short.

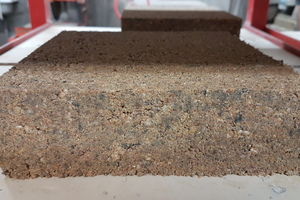

The prototypes were produced on a so-called single block making machine of Kostermann GmbH & Co. KG located in Coesfeld which allowed representing the relations on an industrial machine in good approximation, cf. Fig. 5 on the left. After an alignment of the relevant production parameters on behalf of Rekers, block prototypes measuring 20 x 20 x 6.2 cm³ (length x width x thickness) were produced, cf. Fig. 5 on the right. After a 7-day storage under a plastic sheeting, the blocks had then been stored for additional 21 days in the laboratory at 20 °C and 65 % RH until testing.

In order to verify the performance of the developed concretes, the hardened concrete properties listed in Tab. 5 were checked after 28 days both on the laboratory test cylinders and the test specimens made of the paving block prototypes.

For investigating the water resistance as well as the influence of a storage in water on the strength of the alkali-activated concretes, after 28 days selected test specimens were subjected to an atmospheric water saturation for 14 days. After completion of this saturation, the hardened concrete parameters listed in Tab. 5 were examined again. The results are shown in a graphic representation below.

It should be noted at this point that the range of test specimens per series comprised a maximum of 6 specimens so that the results shown here cannot be regarded to be universally valid.

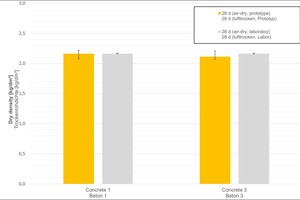

The following Fig. 6 shows a comparison of the dry densities achieved by the developed concretes.

The comparison of the dry densities reveals that the self-developed laboratory compaction process achieving at values between 2.1 and 2.2 kg/dm³ a level similar to the realistic single block making machine. For common cementitious systems, the present production of Rekers achieves slightly higher dry densities in the range of 2.35 kg/m³.

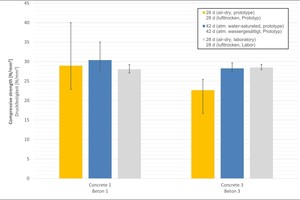

Fig. 7 illustrates the comparative representation of the compressive strengths reached after 28 days stored in the laboratory as well as after a subsequent 14-day storage in water namely after 42 days.

The results reveal that in almost all test scenarios mean concrete compressive strengths between 25 and 30 N/mm² can be identified. The results of the prototype consisting of Concrete 3 are an exception. A noticeable fact in this regard is that the scatter of test results of the paving block prototypes after 28 d is significantly higher than for the test specimens produced in the laboratory. This proves that the self-developed laboratory compaction method has a higher repetition precision. Furthermore, the results are an indication for the fact that higher scatters can occur when using the concretes developed here on industrial-scale plants.

In respect of the subsequent storage of the prototype concretes in water, it may be concluded that they tend to entail two effects. Firstly, a reduction of the scatter of results can be recognized and secondly, an increase in the compressive strength. Thus, the latter result shows impressively that the phases developing the strength of the alkali-activated concrete are resistant to water.

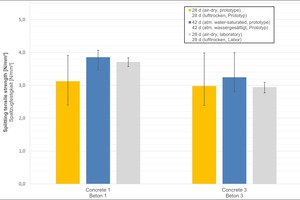

Besides the compressive strengths, the splitting tensile strengths serves as an important quality criterion in the production of concretes for paving blocks. Therefore, Fig. 8 shows a comparison of the measured values of these parameters.

When comparing the mean values and the scatter bands of the two laboratory concretes with each other, it will be noticed that these at 3.7 N/mm² for Concrete 1 are significantly higher than for Concrete 3 at about 3 N/mm². It can therefore be concluded that a paste rich in metakaolin leads to a higher splitting tensile strength.

Owing to the high scatter of results for the test specimens made of the prototypes, they cannot significantly be distinguished from each other, despite the partially clear variation in the mean values. This applies within a concrete group and as well as beyond the two concrete groups. Hence, it can be concluded from the investigations that the prototypes of the two concrete groups have a mean splitting tensile of 3 N/mm² after dry storage.

Similar to the compressive strengths, the subsequent storage in water leads to an increase in strength and a decline in the scatter of measured values, which is to be regarded positively.

When calculating the quotient typical for mineral building materials using tensile strength and compressive strength, this is about 0.13 on average for Concrete 1, about 0.10 for Concrete 3 for the laboratory concretes, whereas in case of the prototypes it is about 0.11 for Concrete 1 and about 0.13 for Concrete 3. A range which is also usual for cement-based concretes.

The following Table gives a summarizing comparison of parameters according to the requirements of Tab. 5 reached by the alkali-activated concretes made of the practice-oriented prototypes.

It became clear that the alkali-activated concretes made of the prototypes will be able to fulfil the requirements on workability, green strength and bulk density. The requirements regarding the degree of compaction and splitting tensile strength are slightly missed, however, those regarding compressive strength were clearly missed, thus inviting to discussion about an existing potential for optimization, which will have to be the subject of further research work.

Even if not all of the ambitious requirements could be met within the scope of this research project, it is obvious that it is possible to develop alternative concretes which, using recycled materials, exhibit properties that are relevant to construction practice.

6 Aspects of sustainability

Against the background of the intended recovery of cement-bound demolition materials, it was impressively demonstrated that it is also possible to reintegrate the fine fraction of cementitious concrete demolition waste into the material cycle as a constituent of an alternative concrete. In addition to this objective, the research was also focusing on minimizing the CO2 footprint of the newly developed concretes.

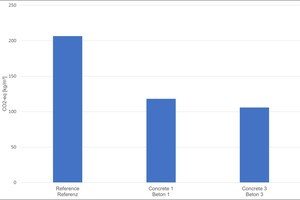

To illustrate this, the CO2 equivalents for the production of one cubic meter of the reference concrete made of cement concrete and the two alternative Concretes 1 and 3 are compared in the following figure.

The cement-bound reference mix design reaches a CO2 equivalent of about 207 kg/m³ of fresh concrete, according to the manufacturer. In case of cementitious systems, the largest CO2 share is introduced by the cement as main binder component with about 780 kg CO2/t cement.

In respect of the alkali-activated concretes, the CO2 equivalent is already reduced by about 43 wt.-% for Concrete 1 with a mixing ratio of 1:3 (crushed concrete sand to metakaolin) with 118 kg CO2 eq/m³ of fresh concrete as against the reference mix design. An increase of the portion of crushed concrete sand to a ratio of 1:1.5 for Concrete 3 has a further positive effect on the CO2 equivalent to 106 kg CO2/m³ owing to a further reduction of the CO2-intensive metakaolin (423 kg CO2/t) [HEA 14] and thus resulting in a reduction compared to the reference of about 49 wt.-%.

7 Conclusion and outlook:

The investigations carried out as part of this research project demonstrate impressively that it is possible to produce alkali-activated concretes based an alternative binder consisting of metakaolin and crushed concrete sand, which in terms of workability and green strength satisfy the manufacturing requirements for the production of concrete blocks on large-scale plants.

However, the results also reveal that there is still need for optimization in view of the high requirements on compactability, compressive strength and splitting tensile strength. This, anyhow, should not obscure the fact that the alternative concretes developed here exhibit material properties that are relevant to construction practice and are comparable to conventional concretes, being used in building construction and civil engineering today.

With regard to ecology, it also becomes clear that there is considerable potential for saving carbon emissions in the newly developed concretes, with reducing the use of natural, not re-growing raw materials substantially. The research work, moreover, demonstrates that there is thus also for the fine fractions from crushed concrete a reasonable way back into new building materials, which closes the material cycle at this point.

In principle, the alkali-activated binders and concretes developed in this project are to be understood as technically useful building materials that can cover a wide range of applications in the production of concrete and concrete products in the future. Against the background of the characteristic values achieved, even the use in reinforced concrete construction is conceivable. Based on the investigations carried out in this regard, continuing research is required in the fields of concrete technology and the durability of the newly developed building materials in order to fully exploit the potential of these building materials that are highly interesting in view of civil engineering and the ecology in the future.

8 Acknowledgement

The authors express their cordial thanks to German Federal Environmental Foundation (Deutsche Bundesstiftung Umwelt - DBU) for generously supporting this research project. Their thanks also go to Klostermann GmbH & Co. KG allowing for the production of the paving block prototypes under realistic conditions.

REFERENCES/LITERATUR