Vision of the future and technological highlights at bauma

At bauma 2025 in Munich, Kniele GmbH, a family-run business based in the German federal state of Baden-Württemberg, will present its latest developments and technological innovations in concrete mixing technology. Since its founding, in 1991, by Erwin Kniele, the company has become established as a leading supplier of customer-specific mixing plants and complete solutions for the construction industry as well as in many other sectors of industry. With decade-long experience and the objective of surpassing even the highest quality standards, Kniele strives for the position as number one in mixing technology – both within Germany and worldwide.

Innovations in mixing technology: the Kniele KKM cone mixer

At the Kniele GmbH exhibition stand in Hall C, Stand 219, the company presents its flagship product: the Kniele KKM cone mixer. Although the basic design of the patent-protected construction is the product of as much as two decades of experience and know-how in a rough production environment, the Kniele KKM being produced today is in every regard new. Available in various sizes and features, the Kniele KKM cone mixer has proved to be pioneering – especially in the area of concrete processing. In particular, the geometric design and the latest agitator adaptations, including smart control, ensure that a maximum of shear forces is applied to the mix. Since the material can thereby be effectively broken down in an unprecedented way, this also results in significant savings in cement, for example. This is an absolutely relevant advantage, especially in the concrete industry – which is currently not only under significant cost pressure, but must also take more and more aspects of sustainability into account. In addition, Kniele KKM is now able to determine the rheological properties of the mix in real time. This ensures accurately repeatable and consistent quality throughout the mixing process and increases overall efficiency and precision throughout the entire production process.

In addition, the Kniele KKM cone mixer can be equipped with optional features, depending on the mixing material and requirement profile, which significantly extends the range of applications and durability. These features include a ceramic trough lining, which reduces wear, and an especially developed high-pressure cleaning system for even faster and more thorough cleaning.

From special mixes to self-compacting concrete: flexibility for today’s requirements

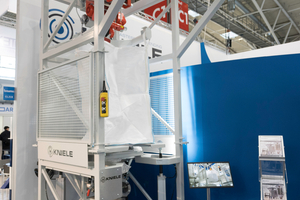

The demand for highly specialized products has substantially increased in recent years. For these requirements, highly diverse additions to concrete are frequently used that, for example, are available as bulk goods. Kniele has quickly reacted to its customers’ new and extended requirements. Many raw materials and additions, delivered in BigBags, require appropriately customized discharge stations as well as reliable processing and material-flow techniques that Kniele optimally serves: e.g., with LC and HC BagBag discharge stations.

Mixing technology and material flow techniques developed by Kniele offer solutions for a wide range of applications – from heavy and lightweight mixes to complex suspensions. Materials such as self-compacting concrete (SCC) and ultra-high-strength concrete (UHSC) – used, for example, with high-quality façade elements, can be produced without problems in Kniele mixers.

Enhanced safety and sustainability through innovative materials technology

An additional focus of recent Kniele developments is on enhanced safety and wear-resistance technology. The service lives of Kniele machines has been considerably extended by optimized agitator arms and even more wear-resistant materials. The safety of the mixer cover has been technically improved to enable operators still more reliable and safe utilization in day-to-day operation. Kniele, furthermore, has developed various mixer gates for meeting the specific requirements for dry mixes, wet mixes and suspensions.

The high level of in-house production depth and know-how at Kniele GmbH enables the company to implement new plants and to upgrade existing facilities with high profitability. The company offers complete solutions tailored to the customer’s respective requirements.

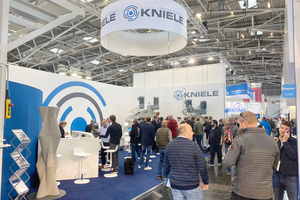

Welcome – Kniele at bauma 2025

The company Kniele invites all interested parties to experience firsthand the technical innovations and comprehensive solutions at bauma in Hall C, Stand 219. The latest-generation Kniele KKM cone mixer and its laboratory variant, as well as a BigBag station, can be viewed live. Interested parties will have the opportunity to talk to experts from Kniele to gain insights into innovative Kniele mixing technology.

With its KKM cone mixer, Kniele GmbH at bauma 2025 is once again setting new standards for the industry, with its latest presentation of impressive technology.