Water savings owing to much better mixing:

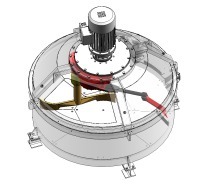

Teka turbine mixer for Hermann Peter

Hermann Peter Baustoffwerke are a medium-sized group of companies with own production facilities located in Rheinau-Freistett and Niederrimsingen near Breisach am Rhein. Since the beginning in 1932, the company has been focusing on innovation, competitiveness and highest demands as regards quality and customer satisfaction. Hermann Peter proudly looks back on a long tradition, along with a wealth of experience gained in the extraction of sand and gravel. The company manufacturers essential building materials, such as ready-mixed concrete, concrete blocks or sand-lime bricks, using the raw materials extracted and treated by themselves.

The project: Replacement of a mixer

Two core concrete mixers are in operation – two Schlosser 2250 core concrete mixers from 1980 – at the production plant of Hermann Peter for manufacturing paving stones. One of those core concrete mixers was to be replaced. The core concrete mixer is not only producing core concrete for paving stones, but also colored concrete for large-sized building components. After their initial contact with Teka at Bauma 2022, the project soon became specific. In April 2023, the contract was awarded to the experienced manufacturer based in Edenkoben. The mixer was supplied in March 2024, being put into operation in April 2024. The scope of supply included the THT G-2-V Teka turbine mixer (further development of the planetary mixer) 1500 liters 1.0 m³, a storage bin for aggregates and hoppers. All other components of the mixing plant could remain in use.

Particularly challenging: The installation

The installation of the new mixer into the plant was particularly challenging, because on the upper side there are the steel structure, feeder and the belt conveyors of the aggregates, on the bottom side there is the mixing platform with the two core concrete mixers that would have to be dismantled. The feeder blocks the installation from the rear. The problem was solved by carrying the individual components of the mixer (motor, upper part with gearbox, mixing pan) onto a scaffold above the bucket conveyor and pushing them through a narrow passage from the production hall into the mixing plant.

The turbine mixer: Technical details

The THT 1500 Teka high-performance turbine mixer (type G-2-V) is equipped with a frequency-controlled 45 kW drive motor and has a maximum concrete output of 1.0 m³ per batch. The Teka turbine mixer has a patented mixing turbine as well as a counter-rotating mixing star. The mixing star and the also rotating discharge paddles and wall scrapers are continuously feeding material to the mixing turbine. This configuration ensures quick, high-performance mixing of the material within a very short time, results in maximum homogenization and an almost straight course of the measuring curve of moisture measurements.

CONTACT

Hermann Peter KG

Rheinstraße 120

77866 Rheinau

+49 7844 4050

Teka Maschinenbau GmbH

In den Seewiesen 2

67480 Edenkoben/Germany

+49 6323 809-0