Water treatment plant for Salzgitter spent nuclear fuel repository delivered to a depth of 1,000 m

All good things are worth waiting for, the saying goes. Likewise, something is happening underground, at last: In Salzgitter in the State of Lower Saxony, construction of the Konrad mine spent nuclear fuel repository is entering its final phase – a challenging project that the ETS Schacht Konrad Feldhaus Bergbau/Schachtbau Nordhausen consortium and AJF Group Engineering GmbH are jointly working on. AJF Group based in Egg an der Günz is supplying the water treatment plant to be commissioned at a depth of 1,000 meters.

Konrad mine nuclear fuel repository project enters final stage

As a pioneer in designing innovative systems for flexible residual concrete water treatment, AJF won the contract, proving that mobile water treatment works everywhere – even underground –, sustainably and in compliance with all requirements. The planning process for the spent nuclear fuel repository project started as early as in 1982. AJF and the ETS consortium comprising the two companies Feldhaus Bergbau GmbH and Schachtbau Nordhausen GmbH are among those involved in constructing this repository designed for low- and intermediate-level radioactive waste. The ETS consortium was contracted with concreting works in the underground mine. If everything proceeds according to plan, the Konrad mine in Salzgitter will commence operations as a deep geological repository in 2030. Currently, radioactive waste is still put to interim above-ground storage on multiple sites spread across Germany.

Putting radioactive waste to permanent storage after construction began in 2009

Miners were still loading and pushing carts at the Konrad ore mine until 1976, when the extracted ore fell short of the competition in terms of its quality. Today, hundreds of meters of massive clay rock and a total mining depth of 1,232 meters make the site exceedingly attractive for the first German repository approved under nuclear law. “Suitable owing to its favorable geology,” said the assessment back in 1982. After a lengthy approval process followed by a public hearing, the Lower Saxony Ministry of the Environment overseeing the project granted approval for Konrad in 2002. Municipalities, districts, parishes, and private individuals filed eight lawsuits against this decision. In March 2006, the Higher Administrative Court in Lüneburg dismissed the complaints while not granting permission to appeal. The Federal Administrative Court confirmed this ruling in March 2007.

What we know for certain is that Konrad’s extensive clay rock strata will prevent water from penetrating into the repository and radioactive matter from escaping for a long time. This has also been confirmed by the Bundesgesellschaft für Endlagerung mbH (BGE), the federal entity entrusted with the construction of the facility: Construction commenced already in 2009, and storage of up to 303,000 cubic meters of nuclear waste is set to begin soon. The containers designed for waste with a maximum radioactivity of 5 × 1018 becquerel need to be fixed in place with concrete. Following the active operating phase, all mine cavities will be backfilled and sealed to provide long-term safety.

Mining development of the repository

Feldhaus Bergbau GmbH & Co. KG and Schachtbau Nordhausen GmbH are working on the underground mining and repository development on behalf of the BMA consortium established for the Salzgitter spent fuel repository project. Converting the old iron ore mine poses quite a few challenges: Two underground mine shafts need to be rehabilitated and equipped with the required infrastructure, including transportation routes, a storage shaft, and storage zones. The entire design must meet the relevant seismic safety requirements. Cooperation between the mining experts at Schachtbau Nordhausen and Feldhaus Bergbau is to ensure smooth on-site processes, including logistics and the supply of construction materials.

The underground infrastructure resembles a small town because it includes service and equipment rooms, a maintenance and assembly yard, a waste collection point, and a fuel store. More than 27,000 m³ of rock were excavated from the bedrock, over 45,000 anchors were placed in the rock, and over 15,000 m² were covered with reinforced shotcrete for this purpose. The second construction phase involved installation of a rigid inner concrete tube. Just like in tunneling, another 20 cm layer of reinforced concrete was applied to the surface.

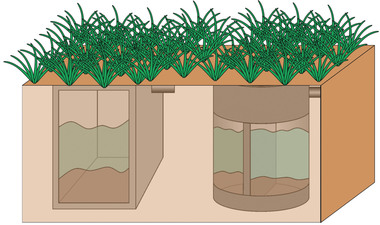

AJF slurry filter press: Dewatering concrete slurry underground

After project completion, nuclear waste will be safely conveyed down the shaft for deep geological storage. At this stage, however, the industrial-scale, environmentally friendly AJF water treatment plant will be sent down this route – ready to save disposal costs in handling concrete slurry and supply residual water for reuse in a fully automated process. The AJF slurry filter press is a highly efficient innovation in residual water treatment that helps companies in the concrete industry handle the volume of slurry generated every day. This process results in 100% reusable water and highly dewatered filter cake – a huge relief for all parties involved because simply disposing of concrete slurry and water into the sewage system is prohibited.

Volatile wastewater volume: Treatment system ensures flexible adjustment

For delivery to the Salzgitter spent nuclear fuel repository, AJF will split the treatment system into several subunits: Piece by piece, it will descend vertically to a depth of 1,000 m in an elevator. The same applies to the employees who will install and commission everything underground, including a closed water circuit. Treatment is exceedingly sophisticated because the wastewater volume is changing constantly, but it is an easy job for a water treatment plant and filter press that adapt to such conditions in a flexible, fully automated process.

In accordance with the German Circular Economy Act, recycling generally has priority over disposal. However, this priority no longer applies if there is a risk of harm to people and the environment. The AJF system, on the other hand, implements such a recycling process even under the most adverse conditions. Since wastewater and filter cake differ from batch to batch, the AJF team of experts also support their customers with filtration or crushing tests as well as water analyses.

Sustainable water treatment offers future opportunities

AJF Group’s ability to innovate tipped the scales in favor of a unique project whose implementation will make history in the context of the challenges posed by the Konrad mine repository. Anyone interested in wastewater/concrete slurry treatment can request their own disposal report on the company website – and visit the proposed nuclear repository free of charge thanks to the service provided by the Konrad information center. The next projects of the specialist for the concrete, quarrying, and tunneling industries are already in the pipeline, which is why AJF managing director Bernd Hahn is always on the lookout for dedicated people who are enthusiastic about the exciting, international field of sustainable technologies and help shape change and the future.

CONTACT

AJF-Group Engineering GmbH

Inneberg 17

87743 Egg an der Günz/Germany

+49 8333 94617-77