Worn concrete mixer components and digital wear maps

This article briefly presents a wear map example of a L-shaped blade mounted on a concrete twin shaft mixer. This evaluation was carried out through a method developed by the University of Perugia that can be applied to both mechanical and biomechanical components, but it was validated for the first time in the study of the blades of a planetary mixer.

In concrete mixers and in general in all machines, the knowledge of how some components wear out is useful both to evaluate their useful life and to optimize their design for reducing consumptions [1-3]. This article briefly presents a wear map example of a L-shaped blade mounted on a concrete twin shaft mixer. This is an experimental evaluation using a 3D optical scanning technology whose results are displayed in color maps describing the distribution of wear over the component’s surface.

This evaluation was carried out through a method developed by the University of Perugia that can be applied to both mechanical and biomechanical components [4-10], but it was validated for the first time in the study of the blades of a planetary mixer produced by Sicoma Srl. (Perugia, Italy).

1 Introduction

Nowadays the environmental impact of a machine or a process is an important industrial focus, therefore companies producing machines must improve the product quality and reduce the energy waste at the same time. To remain competitive, this objective must necessarily be achieved using fewer resources, less time, less money and paying attention to energy consumption [11-16].

In this scenario, the measurement and analysis of loss of material on the components during the working life can be very useful to optimize the machine productivity reducing the absorbed energy [17, 18].

The paper focus on analyzing and evaluating wear and material losses by means the use of 3D optical and metrological scanners. There are many methods to analyze and evaluate wear and material losses. Akkök et al. in [19] classify wear measurement methods into direct and indirect.

In applications where the direct contact with the worn surface is feasible, direct methods are usable and they result to be the best in terms of efficiency, rapidity, and accuracy.

The modern measuring technologies are becoming smarter and smarter in many industrial, medical, and applied research fields [20]. In the field that this paper deals with, the innovative wear measuring techniques can be included in the area of what the authors like to define as “digital tribology”. Digital tribology is definable as the totality of the digital techniques applicable in tribology, for wear detection and evaluation, and for the analysis of contact [21-25], lubricating conditions and deformations [26].

Among the direct and digital methods to evaluate wear, a very smart technique implies the use of optical non-contact profilometers, 3D scanners and microscopes. The use of those instruments is really recommended as it allows great versatility, reliability, and accuracy, as most of the times the use of those instruments does not require the specimen to be dismounted.

Furthermore, excepted the profilometers, they can be the best solution when the specimen has a complex shape. Particularly, the use of 3D optical scanners can give the advantage of being portable, allowing the operator to scan also undercuts in a very simple way. At the same time, some of these instruments are also able to generate a full 3D digital model of the specimen in real time and automatically, in order to evaluate the wear 3D distribution by comparison with a non-worn model [7, 27, 28].

Results obtained from the application of a new wear validation procedure using 3D optical scanners was performed on mixing blades. The method [29] was proposed by the University of Perugia and applied for the first time in the study of mixing components as it can be seen in [30].

2 The twin shaft mixer and 3D scanner

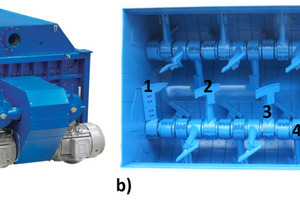

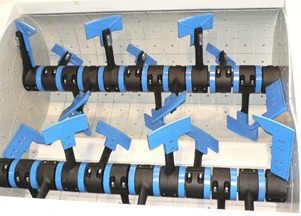

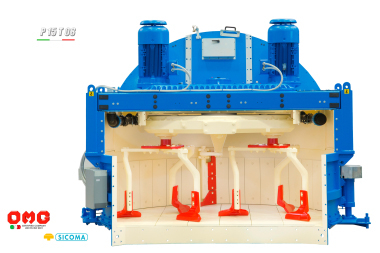

Concrete twin-shaft mixers are horizontal mixers which work with a rotation of two horizontal shafts. Figure 1 shows a kind of these mixers produced by Sicoma Srl.. Typical components of these machines are the motors, one or more for each shaft, the gear boxes, the shafts, the tank, and the mixing organs as blades, arms, and connections.

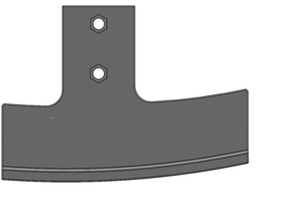

The analysed twin shaft mixer is the mixer MAO by Sicoma Srl., Perugia, Italy that processes 4500 m3 of concrete, with 8 blades for each shaft. In particular, the fourth blade from the left was analysed by 3D scanning directly while it was mounted on the shaft and after it was cleaned from the concrete. The scanning operations were made at three different times: when the blade was new, after 6 months of work and after 12 months of work, called t1 and t2 respectively. Figure 2 shows the analyzed L-blade.

The wear characterization was aimed at studying the wear progress after the different working periods, to characterize the most worn areas. The evaluation was performed by using a metrology grade portable optical laser scanner (FreeScan X7, Shining 3D Tech. Co., Ltd., Hangzhou, China) showed in Figure 3 and a mesh compare software (Geomagic Wrap 2017, 3D Systems, Inc., Rock Hill, South Carolina, USA).

3 Results

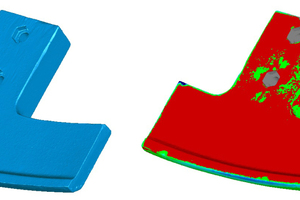

After digital processing of 3D scans, the wear results at the end of time t2 in terms of maps are represented in Figure 4 which shows the coloured map indicating the loss of material due to wear in the various areas of the blade’s surface and shows how the use of the 3D metrology instrument provides a complete scenario of the loss of material over the entire surface of the component.

Considering the lower section of the blade, the initial volume V0 and the current volume Vi, after each test period the wear rate can be calculated according to the following formula.

(1)

The results of the wear rate assessment at time t1 and time t2 are shown in Table 1.

4 Summary

The experimental evaluation of wear of mechanical components is a measure that can be advantageously used to investigate the energy consumption of a machine and possibly to redesign some components to achieve the two main objectives oriented towards sustainability [13]: 1) longer useful life; 2) reduction of energy consumption. This article has shown an example of a 3D digital map where the areas of material reduction due to the exercise are highlighted.

REFERENCES/LITERATURE