BFT-expert-forum “Wetcast” was a great success

15.06.2022Great participation and high satisfaction values were achieved by the BFT expert forum WetCast 2022. More than 50 experts from concrete block- and precast plants as well as from companies of the supplier industry from Germany, Switzerland and the Netherlands followed the call of their industry’s specialist title BFT International to Ulm for the second edition after 2018 - postponed by several months due to Corona.

The BFT expert forum WetCast consisted of a lecture part in the morning in the auditorium of the vocational school for the precast concrete industry, the Ferdinand-von-Steinbeis-Schule (FSS), and a practical demonstration in the afternoon in the workshop of the FSS.

Thematically, the lecture part covered the entire process of WetCast production, starting with concrete admixtures, molds, mixing technology, pigments and plant technology and ending with the underlayment slabs. Jorg Schrabback, Uwe Schäfer, Erik Hertfelder and Dr. Albert Herrmann from Sika kicked off the event with their presentation on "The all-round carefree package" for WetCast production. An overview of Sika's more than 100-year-old history and corporate structure was followed by an overview of the elastomeric PUR-casting resins offered for mold production, as well as tips for using the appropriate release agent, and finally, information on customer requirements for WetCast products and the appropriate concrete admixtures to achieve the required quality.

Silvio Schade, editor in chief of the BFT International, welcomed the participants of the second BFT expert forum WetCast

Silvio Schade, editor in chief of the BFT International, welcomed the participants of the second BFT expert forum WetCast

Figure: BFT International

Trends in WetCast

Senior Sales Manager Jens Maurus from BFT International then explained what the current state of mold technology is and what trends there are in the WetCast sector, standing in for Jürgen Reiser and Jürgen Steiger from Intexmo, who unfortunately fell ill at shortly before the event. The presentation included an overview of the current areas of application of WetCast products in the design of garden, landscape, and traffic areas via the various types of molds and mold receptions and concluded with numerous examples of trend products such as long-format slabs in travertine look, elements in wood look, exposed concrete objects with smooth surfaces or block steps.

"Mixing and concrete batching technology for WetCast production" - this was the title of the presentation by Felix Kniele (Kniele GmbH) after the lunch break. Starting with a presentation of the family-owned company and the Kniele total batching plants, through the various mixing and batching technologies to WetCast molds, the lecture touched on several key topics at once.

In the concluding presentation, Thomas Henke from the Remei/BPB/Betra group reported on the possibilities of factory surface protection for WetCast. The winning of the innovation award of the supplier industry in the context of the Betontage 2020 for the "BPB Eco Spacer" proved the innovative spirit of Remei/BPB/Betra. This product is a non-toxic, 97 % bio-based and biodegradable grit granulate used for transport and storage of patio and walkway slabs as a buffer to protect them from damage.

The guests used the coffee breaks for technical discussions in the accompanying exhibition

The guests used the coffee breaks for technical discussions in the accompanying exhibition

Figure: BFT International

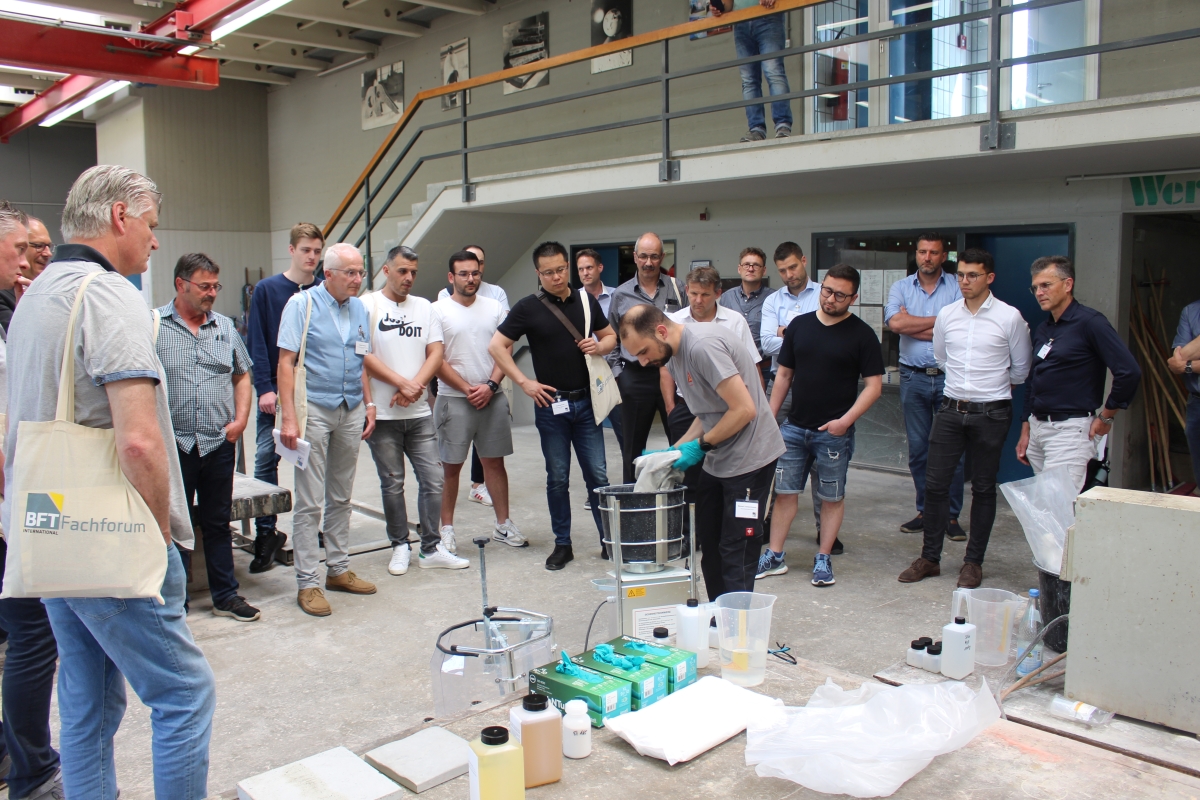

Practical demonstrations in the workshop

Attendees then watched the practical demonstration in the workshop - Manuel Tomaschewski of Sika first prepared a concrete mixture and then poured it into a prepared WetCast mold for a concrete paver.

The event was supported by premium partners Intexmo, Kniele, Remei/BPB/Betra and Sika, as well as partner Rhein-Chemotechnik, all of whom the organizer would like to thank once again at this point. The BFT team was equally pleased with the active support of the Ferdinand von Steinbeis School.

A practical demonstration by Sika Deutschland GmbH in the FSS workshop rounded off the program

A practical demonstration by Sika Deutschland GmbH in the FSS workshop rounded off the program

Figure: BFT International