New Rapid Transbatch for football stadium redevelopment

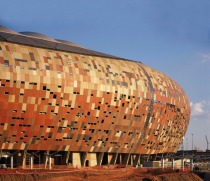

Rapid International recently supplied the Transbatch compact mobile batching plant to Tarmac for on-site production of readymix concrete for the construction of a new 61,000-seat football stadium. The stadium will be the new home of a premiership football team and is due for completion ahead of the 2018/19 season.

The new stadium in London forms part of the larger ‘Northumberland Development Project’, encompassing new homes, a supermarket, a primary school, a public square, a university technical college and new administration buildings for the football club. The club’s project team appointed the London based Mace Group as its partner to oversee construction and completion. Mace has considerable experience at managing large projects with multiple contractors and subcontractors, and has just completed the award-winning New Street Station in Birmingham. Tarmac is the officially appointed on site concrete contractor for the scheme, as agreed by Mace.

Output of up to 100m3 per hour

Rapid’s relationship with the Tarmac Group is longstanding. Tarmac has previously acquired mobile continuous mixing plant and concrete mixers from Rapid’s extensive pan, planetary and twin-shaft range. Tarmac selected the Rapid Transbatch as a result of their requirements for high outputs and ease of mobility to other projects. The project contractors had a prerequisite for concrete outputs of 80m3 per hour which Tarmac had had an obligation to meet. As the Transbatch boasts an impressive output of up to 100m3 per hour, it was an ideal solution.

Transbatch is an illustration of Rapid's forty years of experience, and expands its celebrated existing portfolio of mobile batching solutions. Rapid's Transbatch compact mobile batching plant offers outputs ranging from 40m3 to 100m3 per hour. Fully mobile, the Transbatch features stairs and access walkways which fold and dismantle for transport in a single load road towable unit. Fast set up in as little as five days with no foundation requirements helps to ensure that project timescales are met.

As standard, Transbatch features four 10m3 aggregate bins with pneumatic discharge doors, a 1000mm weighing belt and a 1750kg cement weigh hopper with aeration and pneumatic vibrator. Transbatch includes a built in control room positioned at the truck loading area and an automatic control system with load cells starter panel and pneumatics panel. Twin additive meters with two pumps are also included with the plant, with the option to add extras if required.

The heart of the plant, Rapid's powerful in built Twin Shaft Mixer, which includes extra thick long wearing chill cast tiles and paddles, ensures a thoroughly homogenized mix. The Twin Shaft includes an easy to operate discharge door with two independent hydraulic rams.

As a result of its ease of mobility Transbatch is ideal for remote location projects and construction projects such as, but not limited to, road building, wind farm bases and warehouse flooring.

CONTACT

Rapid International Ltd.

96 Mullavilly Road, Tandragee,

BT 62 2LX Co Armagh/Northern Ireland

+44 2838840671