Compact mixing plant provides concrete for precast manufacturing

At bauma 2007 already, Liebherr showcased the new compact mixing plant in public for the first time. The interest in the flexible plant design is that great that already more than 100 units could have been delivered to customers across all continents in the meantime.

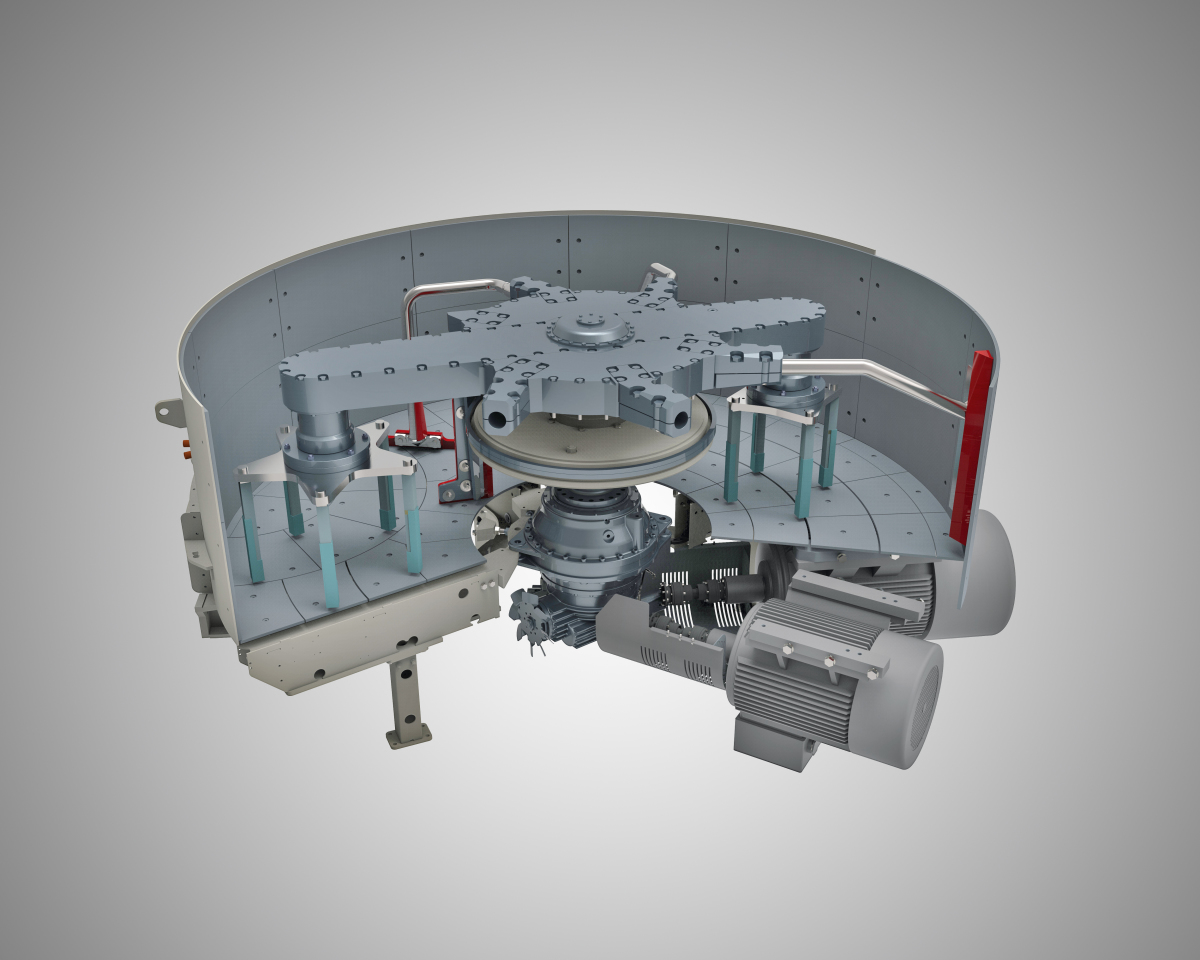

A typical example for the application of the plant is the concrete factory of Dachser GmbH & Co. KG in Türkheim, Germany. There, a Compactmix 1.0 A-R could be incorporated in the existing production hall because of the flexible plant design. A concrete conveyor connects the mixing plant to the precast concrete production. The Liebherr ring-pan mixer type RIM-M is furnished with a mechanical whirler system. In combination with the state-of-the-art microprocessor control system Litronic-MPS II, which is likewise an internal development of Liebherr-Mischtechnik, it is possible to manufacture high-quality concretes according to all requirements and requests. At the moment, concrete C40/50 is mixed in Türkheim using special formulations with high-performance superplasticizer and high-grade cement. Concrete is carried directly to the production hall by means of a conveyor in a traveling feeding box for filling the formworks. The Mindelheim-based building contractor Glass GmbH, being one of the most efficient precast concrete manufacturers in Southern Germany, manufactures special parts for tunnel construction – the tubbing segments – in the new plant in Türkheim. These special segments set standards in respect of compliance with manufacturing tolerances which cannot be compared to conventional precast components used in the construction industry. At present, Glass is manufacturing the tubbing segments for the second pipe of the Austrian Pfänder Tunnel. Within 15 months about 19,500 tubbing segments are produced in a two-shift operation on an up-to-date circulation system. The sizes of the formworks are different, up to 5.8 m³ of concrete are needed per formwork. A ready segment has a weight of up to 15 tons. Apart from the production, Glass is also responsible for the complete precast component logistics, which means that 32 trailer trucks set out from the Türkheim-based factory for the construction site near Bregenz. In order to ensure concrete supply “just in time” also in multi-shift operation and without interruption, the reliability of the mixing plant is of utmost importance. Thanks to the fully-developed technology, robust high-quality components and a galvanized steel structure, the plant design provides for an appropriate disposability. Furnished with an electro-pneumatic concrete chute, the plant is in the position to feed also truck mixers at any time if required and thus can be used parallel in ready-mix concrete production. The basic machine of the Compactmix 1.0 can optionally be combined with in-line silo, pocket silo or star silo. The size of the in-line silo can variably be designed and then it is possible to have a storage volume of aggregates ranging from 70 to 300 m³. Likewise all other mixing plants of Liebherr, many useful options are also available for this plant including, among others, admixture scales, mixer high-pressure cleaner, housing and winter equipment.

Address/Anschrift

Klaus Eckert

Liebherr-Mischtechnik GmbH

Postfach 145

88423 Bad Schussenried/Germany Tel.:+49 7583 949-328

Fax:+49 7583 949-396

Klaus.Eckert@Liebherr.com www.Liebherr.com