The first site for permanent storage of CO2 in demolition concrete in the greater Stuttgart area

22.11.2024

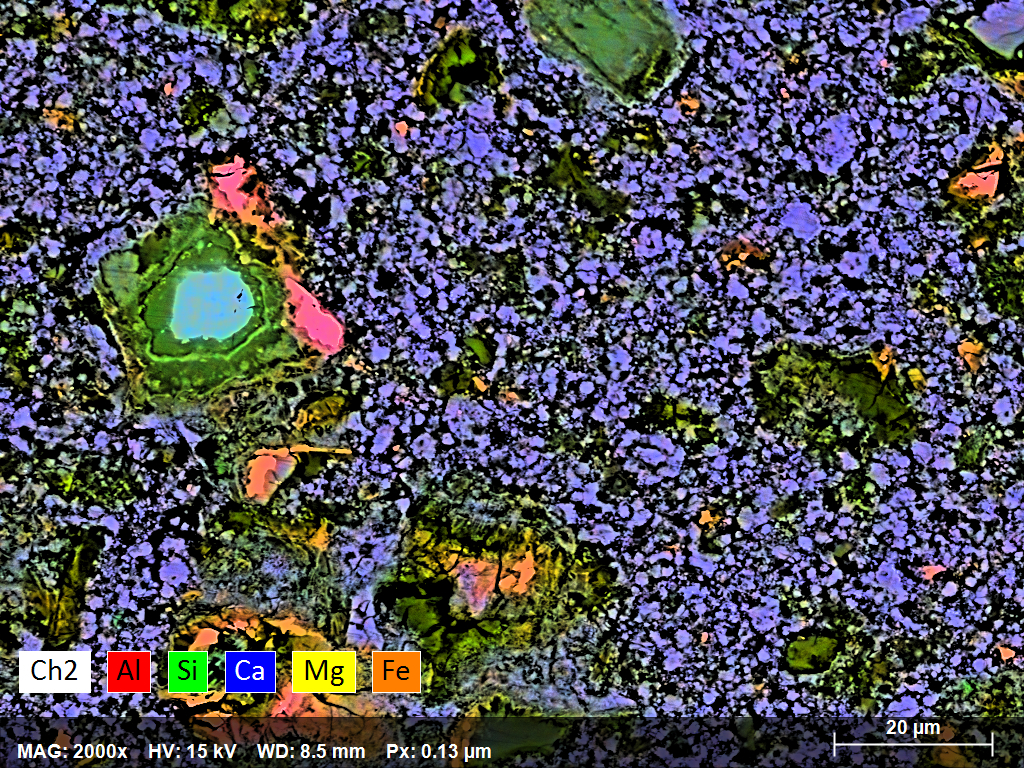

Figure: Neustark

Swiss carbon removal scale-up neustark and family-owned reusable materials specialist Heinrich Feess GmbH & Co. KG have launched the first site in the greater Stuttgart area, in which biogenic CO₂ is stored in demolition concrete and thus permanently removed from the atmosphere.

The new site has an annual storage capacity of 1,000 tonnes of CO₂.

Demolition concrete is the world's largest waste stream

Wiith more than one billion tonnes generated globally each year. In Germany alone, this figure reaches 70 million tonnes annually.

Neustark's technology transforms this mineral waste stream into a carbon sink. CO₂, which is produced as a waste product during biomethane production, is captured, and transported to the nearby production facility of the Stuttgarter construction waste recycler. On-site, the CO₂ is injected into the demolition material in an airtight silo consisting of four chambers, where it is bonded permanently in the aggregate in the form of limestone. Neustark's technology accelerates the mineralization process that stores the CO₂ in the mineral aggregate from several decades to a few hours. The permanent storage of the captured biogenic CO₂ creates negative emissions – next to emissions reductions, a crucial pillar in the path towards net zero.

The potential of this solution is sizable: each ton of concrete can permanently store on average 10 kilograms of CO₂. That means that in Germany, via this mineralization technology, up to 700,000 tonnes of CO₂ can be stored and removed permanently from the atmosphere per year! This local carbon capture and storage (CCS) approach provides an alternative to both local underground CO₂ storage and the transportation of excess CO₂ to North Sea geological storage sites, which have been central to recent discussions in Germany.

“Neustark and Feess share a vision of creating positive environmental impact. Feess has done some impressive a pioneering work in circular building materials in Germany, and our partnership builds on that: After Feess first tested our mobile technology for CO₂ storage, we are now proud launch neustark’s second site in Germany—and the first in the Stuttgart area—with Feess. This is a milestone for onshore CO₂ storage and removal in Germany. Now, public and private sector demand for carbonated building materials, along with supportive legal regulations, is urgently needed to advance our efforts,” says Valentin Gutknecht, founder and co-CEO of neustark.

“We chose to partner with neustark to launch this innovative technology because it integrates perfectly with our on-site concrete recycling and production process and makes it even more sustainable. We’re excited to be the first to store the hundreds of tonnes of CO₂ permanently in demolition concrete in the Stuttgart region. At Feess, circularity is deeply rooted in our corporate DNA. With neustark's technology, we’re taking an important step towards a truly circular economy and greater sustainability in the resource-intensive construction industry,” says Walter Feess, former managing director of Feess.

Another milestone on the way to removing 1 million tonnes of CO₂ in 2030

Next to the site in Germany, neustark has recently launched two more storage sites with Swiss construction company Montebello AG in Pontresina (Graubünden, Switzerland) and Ch. Gerster AG in Liechtenstein, as well as one capture site with SIG in Geneva. In addition, neustark has opened its first CO₂ storage site in the United Kingdom together with Aggregate Industries (part of the Holcim Group). A total of 22 carbon capture and storage facilities are already in operation, with 40 more in the planning and construction stages.

All of these recently opened plants are further important steps for neustark's goal of permanently removing one million tonnes of CO₂ in 2030.

CONTACT

Neustark AG

Freiburgstrasse 251

3018 Bern/Switzerland