Carbon in concrete: Empa presents research results

18.01.2024

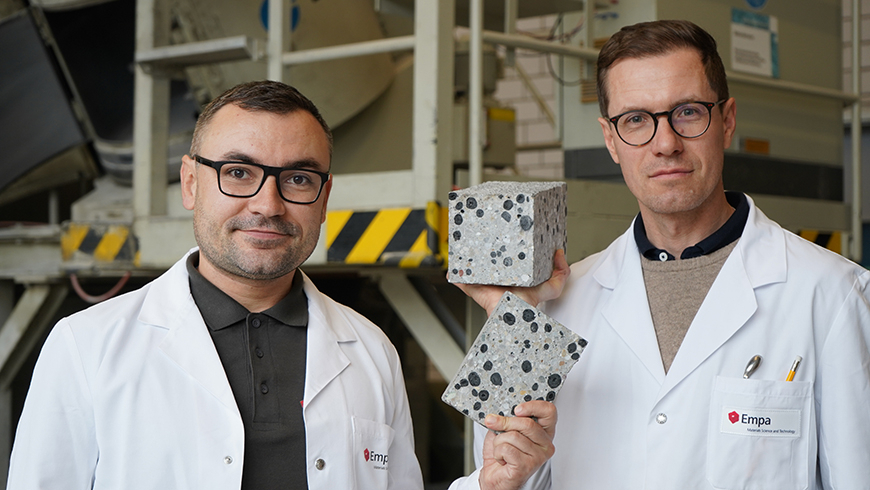

Empa researchers: Mateusz Wyrzykowski (right) and Nikolajs Toropovs (Figure: Empa)

Empa researchers: Mateusz Wyrzykowski (right) and Nikolajs Toropovs (Figure: Empa)

The construction industry as a CO2 sink? Researchers at Empa's Concrete & Asphalt lab are working on this. By incorporating biochar into concrete, they are exploring the potential of CO2-neutral or even CO2-negative concrete. For optimal applicability, they process the biochar into pellets and use them to replace conventional aggregates.

To achieve the goal of a climate-neutral Switzerland by 2050, strategies and processes with a negative CO2 balance are necessary. These so-called negative emission technologies (NET) are intended to counterbalane the remaining "hard-to-avoid" emissions in 2050 and should help ensure that we eventually achieve net zero. As one of the main emitters, the construction sector has a particular obligation. Around eight percent of global greenhouse gas emissions are caused by cement production. At the same time, initial efforts are emerging to use the construction sector, with its massive consumption of resources, as a possible carbon sink. What sounds paradoxical will succeed if we start "building with CO2" – or rather, using carbon to produce building materials and thus removing it from the atmosphere in the long term. For such visions to become reality, a great deal of research is needed – such as is currently being done at Empa's Concrete & Asphalt lab. A team led by Pietro Lura is developing a process for integrating biochar into concrete.

Difficulties due to porosity

Figure: Empa

Figure: Empa

Biochar is produced by a pyrolytic carbonization process of biomass in the absence of oxygen and consists to a high extent of pure carbon – the carbon that the plants have extracted from the atmosphere in the form of CO2 as they grow. While CO2 is emitted when plants are burned, it remains bound in the biochar over the long term. The first concrete products with integrated biochar are already on the market. However, biochar is often introduced into the concrete untreated, which can lead to difficulties. "Biochar is very porous and therefore not only absorbs a lot of water, but also expensive admixtures used in concrete production," explains Empa researcher Mateusz Wyrzykowski. "Moreover, it is difficult to handle and not completely harmless either." The fine coal dust is problematic for the respiratory tract and carries a certain risk of explosion.

For these reasons, the researchers propose in a paper that has just published in the Journal of Cleaner Production processing the biochar into pellets. "Such lightweight aggregates already exist from other materials such as expanded clay or fly ash. The knowhow in handling these materials is available in industry, and this increases the chances that the concept will be put into practice," says Wyrzykowski.

Net zero at 20 percent share

To produce the pellets, the team used a concrete mixer with a rotating pan in which they mixed the biochar with water and cement and, as a result of the rotation, obtained small pellets with a diameter of between 4 and 32 millimeters. In turn, they used these pellets to produce normal concrete of strength classes C20/25 to C30/37 – the classes that are most widely used in civil engineering today. "With a proportion of 20 percent by volume of carbon pellets in the concrete, we achieve net zero emissions," says Mateusz Wyrzykowski. That is, the amount of carbon stored offsets all the emissions produced in the production of both the pellets and the concrete. While the limit has probably not yet been reached for normal concrete (density between 2,000 and 2,600 kg/m3) with 20 percent by volume, the negative emission potential is particularly striking for lightweight concrete (density approx. 1,800 kg/m3): An admixture of 45 percent by volume of carbon pellets in the concrete leads to total negative emissions of minus 290 kg CO2/m3. By comparison, conventional concrete emits around 200 kg CO2/m3.

Carbon from the atmosphere

For laboratory head Pietro Lura, research in his lab is a crucial contribution to achieving climate targets. He does not see biochar, which has served as a model material in current research, as the most important source of carbon. Rather, he draws attention to the broad concept "Mining the Atmosphere", which several labs at Empa are pursuing: the production of synthetic methane using solar energy, water and CO2 from the atmosphere in sunny regions of the world, and the subsequent pyrolysis of the synthetic gas. "This yields hydrogen, which can be used as an energy carrier in industry or mobility, and solid carbon, which we can process into pellets – like biochar – and incorporate into concrete," explains Lura.

Further Information

Prof. Dr. Pietro Lura

Concrete & Asphalt Lab

Tel. +41 58 765 4135

Dr. Mateusz Wyrzykowski

Concrete & Asphalt Lab

Tel. +41 58 765 4541

CONTACT

Empa

Überlandstrasse 129

8600 Dübendorf/Switzerland