First Peri school in Kenya: Hollow core blocks „TwistBlock" for new opportunities

19.04.2024

Figure: Peri SE

Figure: Peri SE

The very first Peri school in Kenya opened its doors at the end of February 2024 for over 200 children. In Kibera, the largest slum in Nairobi, the first school in the Peri sustainability initiative “Building Sustainability” was built in less than a year. In collaboration with the non-profit start-up “Start Somewhere”, Peri developed what are known as TwistBlock Moulds for hollow concrete blocks, which were designed specifically for use in slums due to the simple and flexible manner in which they can be used. The new school building has created not only learning spaces, but also new local job opportunities.

For vocational prospects

Over 200,000 people live in Nairobi’s largest slum, where life on the streets dominates everyday life. Densely clustered corrugated iron huts leave the children barely any space to play, and an education is not something that can be taken for granted. To pave the way for vocational prospects, Peri, in collaboration with the non-profit organisation Global One Foundation, decided to build a new, three-storey primary school, which will provide ample space for play and education. Above all, however, it will provide pupils with opportunities for the future. After all, only those who can read and write will have the opportunity to find work outside the slums later down the line.

TwistBlocks – a building block for new opportunities

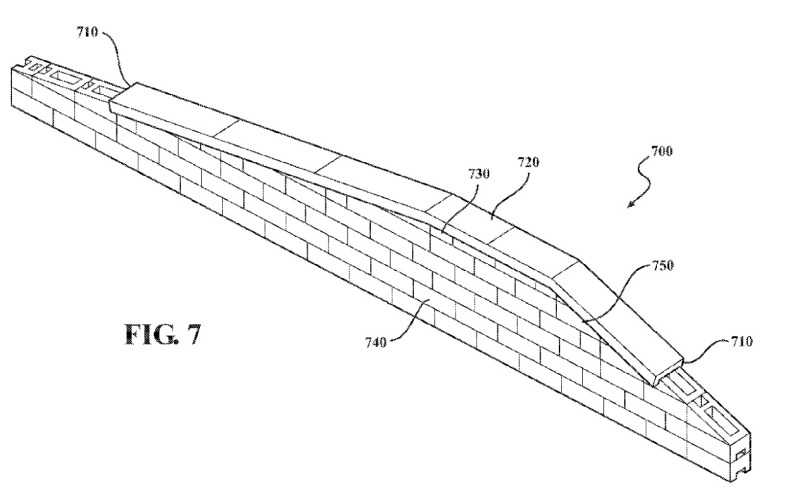

The construction system offers many benefits. The TwistBlocks are hollow on the inside and also very narrow, which means that only a minimum of resources are required for production. What’s more, the TwistBlocks can be disassembled if necessary and reused to a maximum extent of 80%, making construction in slums particularly cost-efficient, safe and sustainable. Blocks are produced using Peri’s TwistBlock moulds in local factories in Kenya and South Africa, creating additional local jobs.

The walls of the school in Kibera are made up of 7,000 TwistBlocks. The fire-resistant blocks feature an impressively simple plug-in system which, in addition to being quick and easy to use, allows the ground plan to be designed flexibly in confined spaces. The cavity inside the blocks also ensures good insulation and pleasant room temperatures in summer and winter. The construction process is therefore very straightforward and requires neither mortar nor trained bricklayers. With a construction time of only one year for the school building, the TwistBlock method sets new standards in terms of rapid construction.

Peri is aiming to build a new school every year as part of its “Building Sustainability” initiative. There are already plans for a Peri school in Cape Town and one in Manila. With this approach, Peri intends to set the ball rolling on new prospects for the future – worldwide.

CONTACT

Peri SE

Rudolf-Diesel-Straße 19

89264 Weißenhorn/Germany

+49 7309.950-0