Kraft Curing Systems for new concrete pipe production hall in Texas

18.03.2024

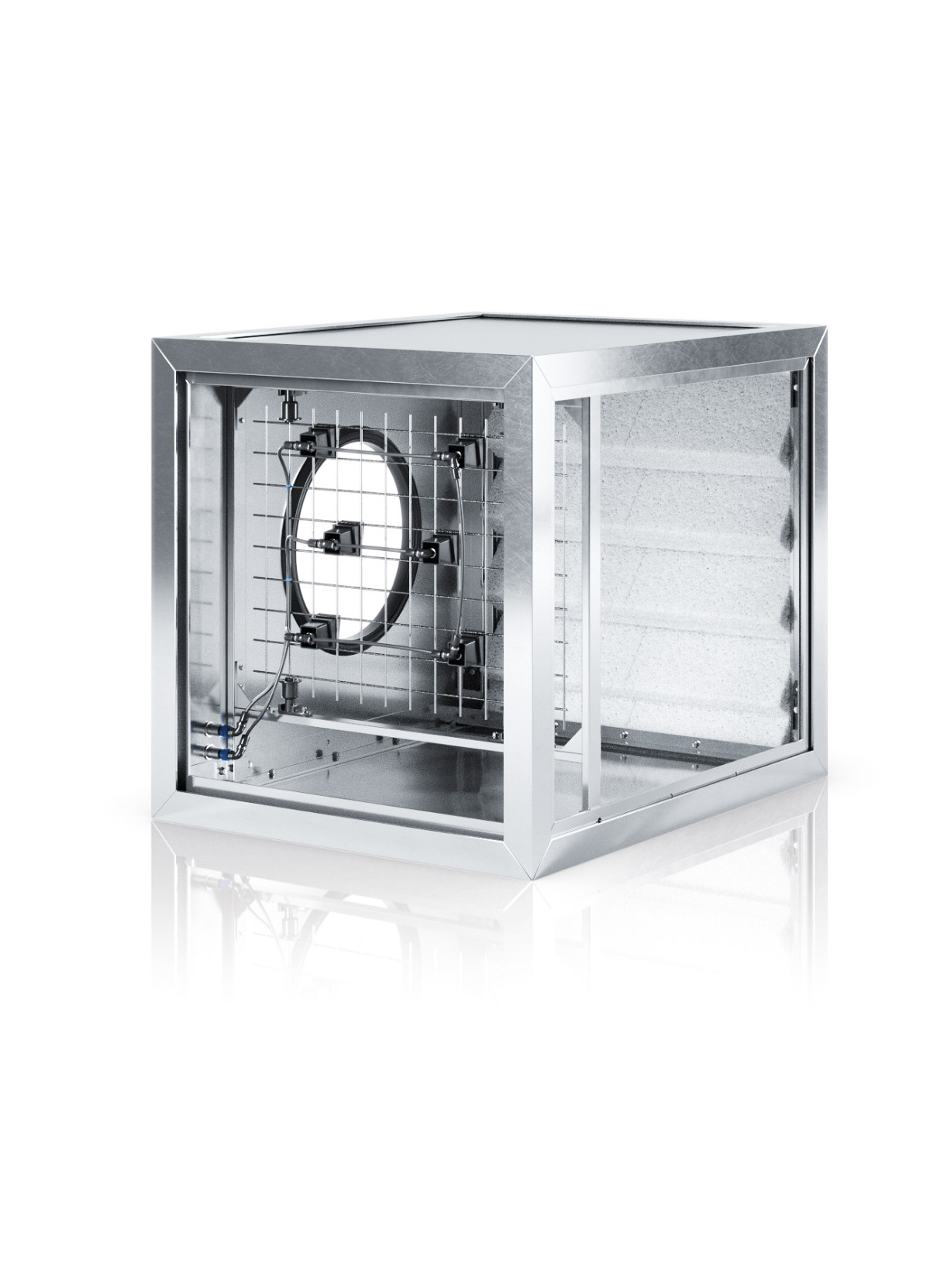

Figure: Kraft Curing

Figure: Kraft Curing

While wrapping up the planning for their new concrete pipe production hall, Texas-based Capital Precast, a producer of high-quality precast concrete sanitation, electrical/communication structures, and other utility products, turned to Kraft Curing Systems to provide their concrete curing solution.

The containerized vapor curing system, installed in their new production building located in San Marcos, Texas, provides accelerated concrete curing via a KC 50-2S direct-fired vapor generator, insulated steel vapor distribution pipe with flexible high temperature hoses and “turtle” diffusers, motorized stainless steel valves, and temperature sensors for automated control of the entire concrete curing process.

Controlled addition of heat and humidity

Concrete pipes are produced on an open floor and cure in retractable enclosures, maintaining ideal curing conditions at a temperature of 140°F and 100% humidity. The enclosed environment prevents evaporation and draughts that can cause concrete pipe to bend (non-reinforced) or crack (steel reinforced). Significantly reduced hardening times, extremely strong bells and spigots as well as a higher surface density is achieved with the controlled addition of heat and humidity. The tarp doors, located at either end of the curing tents, along with the tracks, ensure effortless and rugged operation.

Figure: Kraft Curing

Figure: Kraft Curing

Other benefits of the Vapor System include:

– 98% operating efficiency

– 60% lower operating cost than a steam boiler

– Fully automatic and low-pressure operation

– Lifetime combustion chamber warranty

CONTACT:

Kraft Curing Systems GmbH

Muehlenberg 2

49699 Lindern/Germany

+49 5957 96120