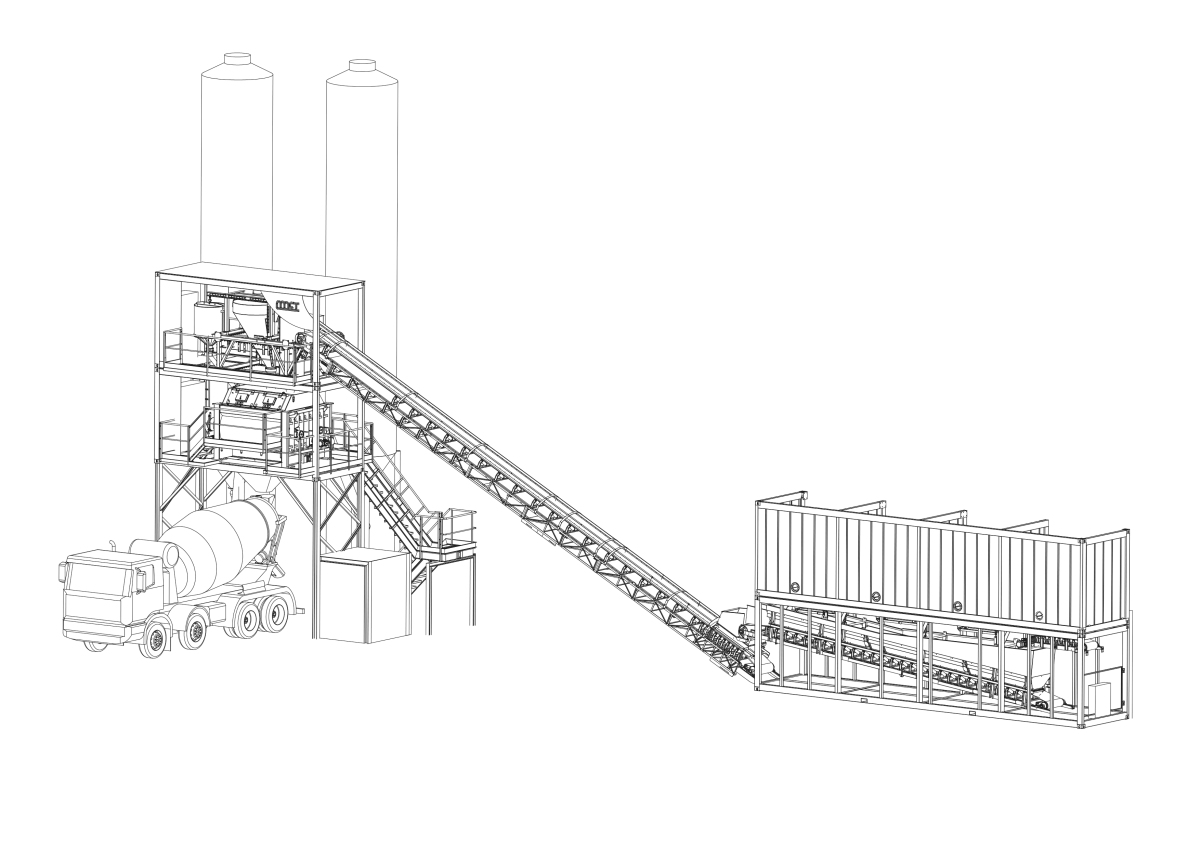

MCT twin lane plant for largest concrete plant in Canada

30.07.2024

Figure: MCT Italy

Figure: MCT Italy

Among the markets along the Atlantic coast, the Great Lakes and the Mississippi, none has impressed as much as the one in Toronto, which thanks to a study of eco-sustainable materials continues to be fundamental in this sector. Due to the largest presence of cement in the Toronto area, combined with a significant housing market and the possibility to expand north, south, and east, Viola Ready Mix Inc. decided to build the largest concrete plant in Canada.

Largest concrete batching plant in Canada

Viola Ready Mix, a division of the Viola Alliance Group, is founded on expertise that has been developed over four decades, new technology in the modernizing of the Ready Mix Industry, professional, dependable customer service with a strong commitment to Quality and Safety. Based in Markham, Ontario, their mid-sized construction company is known for producing and selling high-quality ready mix concrete. Strategically located in Markham, their flagship plant has been designed and constructed to be the largest concrete batching plant in Canada. The cutting-edge batching plant was specifically designed to meet and exceed the growing concrete demand and delivery challenges of the GTA, ranging from small-scale projects to large-scale superstructures. Viola prioritizes safety, efficiency, customer satisfaction and use their advanced ready mix concrete batching plants with a team of industry experts to exceed expectations on every project. Viola provides professional, dependable customer service, and place an unwavering emphasis on safety in all aspects of their operations. If you need top-quality ready-mix concrete, Viola has the expertise and resources to deliver exceptional results.

Figure: MCT Italy

Figure: MCT Italy

Twin lane plant for more than 500 m3/hour output

MCT Group Inc. has equipped a twin lane plant for more than 500 m3/hour output. Anchoring each is a holding hopper and 5 m3 Sicoma 7500/5000 twin shaft mixer, which in two rapid cycles can charge entire trucks with typical loads in three to four minutes.

The new Viola Readymix flagship is located on a 14-acre site north and east of Toronto. It is a vertical tower batching plant with no. 2 aggregate loading systems, no.2 independent materials dosing lines, feeding the 2 twin shaft mixers 7500/5000 for 2 separate trucks feeding lines. Each with a max capacity of 200 m3/h – 260 cu.yd/h of high quality concrete in 24 hours/day shifts. Independent dual aggregates loading system by 2 x 40 ton primary hoppers, 2 buckets elevators 107’ tall and 2 dispensing conveyors on the top of the tower, fully automatic. Aggregates storage with 8 compartments for a total storage of 600 ton with extracting gates and belts to feed both lanes and 8 cement silos 110 ton capacity each with screw conveyors. The tower is complete with supporting structure hot dip galvanised for the entire plant and silos, including integrated supports for cladding enclosure, and MCC/control room. The plant features a complete control system type MCT-CompuNet for the management of the entire plant, including recycling system (from Enviroport) and integrated with dispatching system (from MPAQ). 40 mixer trucks run on the MPAQ Automation Insight Dispatch platform, that is fully integrated with the MCT-CompuNet plant control package.

New companion asphalt operation

Viola has also launched a companion asphalt operation at Markham where abundant bunker block contained aggregate stockpiles separate the concrete and asphalt plants. This stockpile configuration reflects a space saving material handling system that MCT’s engineers incorporated as part of the twine lane plant design.

Viola has worked with Euclid Chemical Canada on the V-ECO offerings, along with a full schedule of decorative, self-consolidating, structural shotcrete, high early strength, ultra-high performance and low shrinkage concrete mixes.

“We are strategically located across every major highway, each plant supporting one another and spaced on average travel times under 30 minutes,” says Viola ReadyMix President Eric Barbosa. ”The Markham plant is built for volume work and specialty concretes, including our V-ECO series mixes for LEED projects and those where customers seek lower carbon footprint than conventional orders. We also invested in a premium concrete reclaimer and storage tanks to reduce material waste and enable full water recycling.”.

A close and successful partnership

“We at MCT are extremely proud of this partnership with Viola ReadyMix, where we found a great team of people who got immediately on-board this new technology and partnered with our crews to ensure the quickest startup of this flagship installation,” says MCT VP of Operations Alessandro DiCesare. “Their care of the quality of every process makes the performances of this production plant quite unique in the GTA. The result of years of engineering and development of MCT in this ReadyMix wet plants field is now clearly tangible also in North America and provides our partners the best tools to boost their business, which is ultimately our main goal”.

CONTACT

MCT Group, Inc.

9190 Double Diamond Parkway Suite120

89521 Reno, NV/USA

+1 775 313 0708