3D printing for the flexible and environmentally friendly production of concrete parts

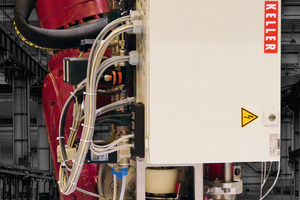

The machinery and plant manufacturer Keller, with its headquarters in Ibbenbüren in North Rhine-Westphalia, is one of the most important companies of the region. For many years, Keller has been developing plant and machinery solutions at the highest level not only for the heavy clay industry but also for other building materials. An interesting new development is the Keller 3D concrete printer “3DCP”.

Digitalization in the building sector

The introduction of digital printing technology is transforming the world‘s traditional construction methods in the building sector. The global visionary interest in serial and modular 3D concrete printing “3DCP” is also increasing to the same extent.

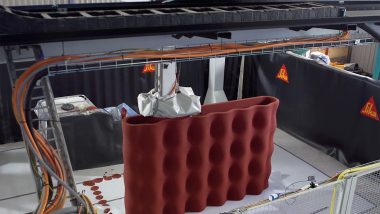

Keller recognised the growing potential of using additive manufacturing in combination with 3D concrete printing in the building industry a few years ago and invested in research and development projects to realise a fully automated 3D concrete printer based on an industrial robot application. The new possibilities of 3D concrete printing application paired with a linear axis system and the addition of a colouring medium in the print head are numerous. An industrial robot in combination with a linear axis system offers a wide range of possibilities in the design and function of products.

3C/three-component 3D concrete printing

3C refers to the number of components in a material to produce the final product. These can be processed with Keller‘s high-tech 3D concrete printer. The fibrous micro-concrete system essentially consists of the components dry mortar, superplasticizer and accelerator. The patented mixing system requires a mixing time of only 3 seconds. With the micro-concrete, a precise and high-quality print can be produced even at a very fast printing speed of 0.3 - 1.5 t/h. The accurate grain size distribution ensures a smooth and aesthetic object surface.

Affordable housing units

The construction of affordable housing units usually depends on two main variables: the cost of the materials used to build the housing units and the structural size. Significant advances in off-site construction can provide innovative solutions for affordable housing. The intelligent combination of the fully automated Keller 3DCP technology and the micro-concrete system results in a remarkable synergy that combines numerous environmentally friendly aspects.

Better CO2 balance

The micro-concrete system itself is an environmentally friendly technology developed with a focus on sustainability. Compared to conventional concrete compositions, the micro-concrete system has a better CO2 balance. In combination with Keller 3DCP printing technology, the environmentally friendly advantages are multiplied. 3D concrete printing allows for precise and efficient use of materials, reducing the overall amount of building material required and therefore taking fewer resources from the environment.

In Keller‘s technology centre, the future-oriented 3DCP technology is constantly being further developed in order to implement technical solutions in practice together with interested parties.