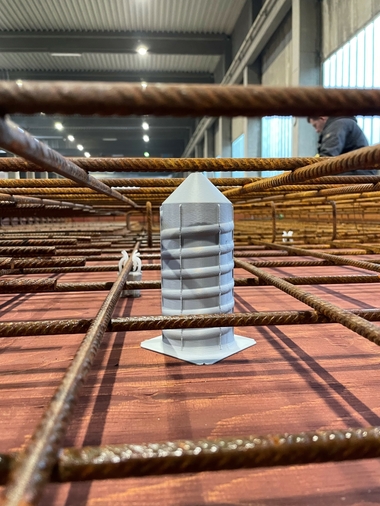

Innovation: 3D printing system for additive manufacturing of recess formers

The 3D printing system for additive manufacturing of recess formers by Kühling & Kühling offers a turnkey package for the precast concrete industry. The combination of high-performance large-sized 3D printer and an industry-specific digital building component catalog provides several advantages, which are related to both the production process and the finished products themselves.

Time and cost savings

The 3D printing process of recess formers can reduce the absolute production time significantly. Traditional methods for the production of recesses can be very time consuming, in particular, in case of complex shapes. With the aid of 3D printing, it is possible to produce recess formers fast and directly according to digital designs (created internally or taken from the building component catalog) without the need of manufacturing elaborate formwork or molds. This not only reduces the production time, but also the associated costs.

Higher flexibility and precision

Recess formers in almost any shape and size can be manufactured with the aid of 3D printing. This allows the realization of complex geometric shapes, the manufacture of which would be difficult with traditional methods or impossible at all. The manufacturing process can be adapted rapidly to the specific design requirements, what simplifies the production of customized precast concrete components and reduces the time for post-processing considerably.

More sustainable production due to reduced material waste

Since 3D printing is an additive process in which the material is added there where it is needed, it is possible to reduce the material waste considerably in comparison to conventional production of recess formers and therefore the production process can be provably made more environmentally friendly.

Easy entry into the technology

The combination of 3D printer and digital building component catalog even allows companies without own experience in 3D modeling to benefit from the advantages of 3D printing. In conclusion, these 3D printed recess formers provably can increase the efficiency, flexibility and sustainability in the precast concrete industry, which results in improved products and processes. For more information please see BFT 02/2024 pages 8/9.

CONTACT

Kühling&Kühling GmbH

Ricklinger Straße 2-6

24610 Trappenkamp/Germany

+49 431 98352473-0