Alternatives to heat curing

In the production of precast elements, special focus is given to optimizing early strengths. High early strengths are a prerequisite for two-shift or three-shift operation with the corresponding formwork cycles and high production output. These goals are typically achieved by using cement-rich concrete formulations with low water-cement ratios and high-strength Portland cements. Heat curing is also applied in many cases. This still widespread course of action is not only the opposite of a sustainable concrete design but may, in the case of heat curing, also result in serious problems with concrete durability.

In the past decade, alternatives to conventional heat curing have been increasingly introduced into the market. These are both high-performance quick-setting cements and highly efficient accelerating concrete additives. Contrary to earlier approaches, these acceleration systems are based on the principle of heterogeneous seeding and do not pose a risk to the reinforcing steel.

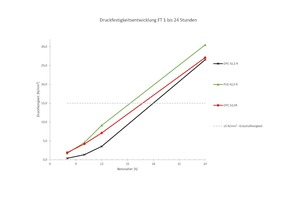

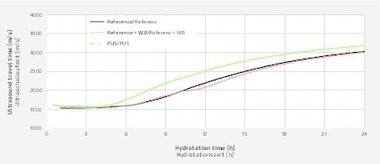

Another option for controlling the hardening behavior of cementitious systems is the use of power ultrasound. Power ultrasound (PUS) refers to ultrasound with frequencies between 20 - 100 kHz. The cavitation effect permits the induction period of the alite reaction to be shortened by means of PUS, and seeding for the C-S-H phase formation to be significantly intensified. The associated acceleration of the hardening process can be used, for example, to substitute heat curing or to allow the use of cements of a lower strength class (Fig.). The PUS concept has meanwhile moved beyond the research and development stage. Commercially applicable acceleration concepts using PUS are now on offer by SonoCrete.