New perspectives for the precast concrete industry

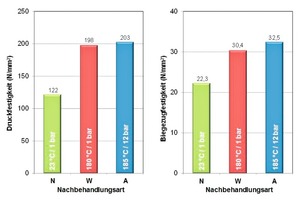

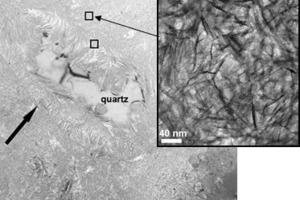

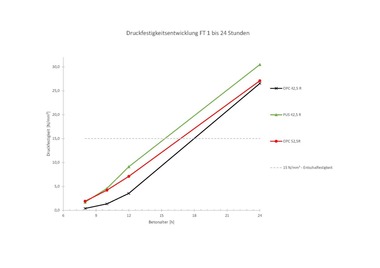

The structure of UHPC is characterized by a densely packed matrix with only a small number of voids; it can be enhanced further by heat curing or hydrothermal treatment (autoclaving) subject to water vapor pressure. Heat curing of concrete is commonly applied in the precast industry in order to shorten its setting time and achieve higher early strengths.

In the autoclaving process, the concrete is additionally subjected to water vapor pressure, which significantly improves the conditions for hydration. This method is known from the autoclaved aerated concrete industry where the production of large elements is very common.

Comprehensive tests were carried out at BAM Bundesanstalt für Materialforschung und -prüfung; Federal Institute for Materials Research and Testing in order to determine the influence of heat curing and autoclaving on the properties of UHPC with and without steel fiber reinforcement. These tests were to clarify the type and...