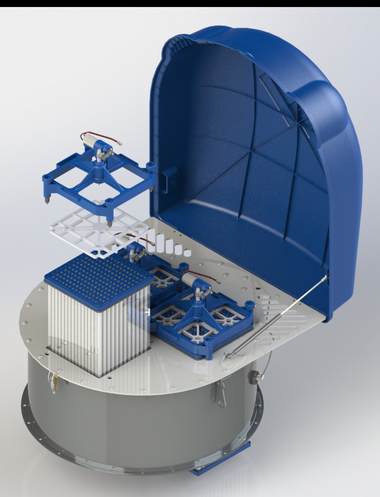

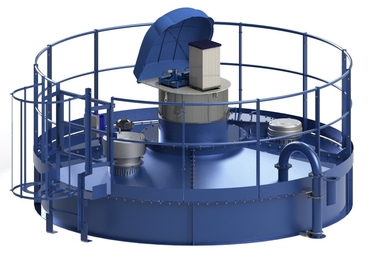

Silotop® and Hoppertop®

Since production started in 1998, more than 25,000 Silotop® filters for ventilating and dedusting silos have been successfully used in applications worldwide. Owing to industrial production methods and hence low production costs, Silotop offers a good price-performance ratio and, according to the manufacturer, meets the most stringent environmental requirements. In time for the bauma exhibition, WAMGROUP® has expanded its range of dedusting filters by adding the new Hoppertop®.

Silotop was originally designed for cement and similar materials but can be used for all types of dust, provided these are dry and do not tend to consolidate under pressure.

The Silotop® filter has a stainless steel housing and is fitted with a silo flange connection. The special design of these tried-and-tested Polypleat® filter elements provides an optimum ratio of filter surface to housing volume.

The compressed air cleaning system is an integrated part of the hinged weather hood and is extremely maintenance friendly. The dust suspended in the air flow is separated by special filter...