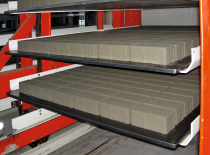

Mobile calibrating system

Depending on the material and the kind of use, production boards made of wood or plastics wear out as a result of abrasion at the surface. Owing to different surface conditions, it is then difficult to mount the boards flush with the mold resulting in small joints through which concrete may leak. Because of this, the product may get an unwanted shaping. At such points, a board shows more and more signs of wear until it is no longer possible to use the same. Dutch Board Calibration BV offers a possibility for refurbishing with its mobile calibrating system.

With the mobile calibrating system, the Dutch company provides a possibility for refurbishing production boards on both sides that are made of soft and hard wood as well as plastics. The system is installed on a low bed truck and grinding is effected in the factory directly, so as to have as little impact on the production process as possible. This is an inexpensive alternative to replacing worn out boards by new ones.

The boards are retrieved from the board buffer of the manufacturing plant in piles and are moved by means of a forklift truck to the mobile calibrating system. The mobile...