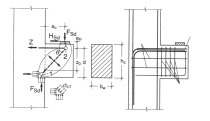

Hidden connection for beams with PCs corbels

A modular hidden corbel, PCs is a great choice for creating a joint in structures with steel beams, composite beams, reinforced and pre-stressed precast concrete beams. The cast-in part enables straight mold walls while a bolted bracket offers superior adjustability and high resistance. With PCs Corbel, you can connect as many beams to the columns as the cross-section can fit. PCs Corbel also allows for flat ceilings and maximum space between the floors – a benefit that resonates with the architects, constructors and investors alike.

Slender columns

PCs Corbel doesn’t need a special corbel mold and a straight formwork can be used for casting the columns. In addition, PCs Corbel doesn’t need a heavy reinforcement either, a fact that makes for smoother precast production as the space in the mold is often limited.

Thanks to the superior adjustability of PCs Corbel, beams are easy to install on site. In addition to vertical, horizontal and beam length adjustment, PCs Corbel can also accommodate fabrication and erection tolerances in expected deviations.

Meet architects’ and investors’ needs

Hidden corbels can be used for clean looks in architecturally ambitious projects. A prime example is the new building for the Tate Modern museum in London. Opened in 2014, the new building rises to 65 m in 11 levels and offers 23.000 m2 of new display space to increase the overall space of Tate Modern by 60 %.

The most attractive part of the building is its form, rational and very irrational at the same time. Four of the building’s façades are vertical and four inclined, creating pyramidal shapes when looking from the entrance of the Switch House. Connecting beams to inclined columns was a challenge solved with customized PCs Corbels.

“The edifice of the building is very important. People should be able to see through the building both literally and figuratively,” says Jim Deryckere, Sales and Project Manager at Valcke Prefab Beton. “As the structure doesn’t have usual concrete corbels, it looks as if the beams float in air between the columns – this gives a very light touch to the building.”

A choice of column connection type can have a significant impact on the profitability, as demonstrated in TaunusTurm project. The building site was located in the middle of the densely populated city-center and space was a major challenge. Also the surface area and storage capacity in the upper floors of a tall building was very limited.

To save both time and space, PCs Corbels were chosen in order to cast the center lift shafts by slip forming method and a climbing formwork. "We only considered a construction using Peikko’s PCs Corbels. No other system available in Germany would have allowed us to construct the TaunusTurm as quickly and economically," said a member of the Züblin planning team.

Approved by Deutsches Institut für Bautechnik

PCs Corbel has received a technical approval from Deutsches Institut für Bautechnik (DIBt), German Technical Approval Body. Currently the approval covers two corbel sizes – PCs 3 and PCs 5. The extension of DIBt Approval to PCs 7 and PCs 10 is expected in 2017. An approval granted by DIBt is considered as a strong reference in Central and Eastern Europe.

As an additional bonus, the full scale tests revealed that the amount of supplementary reinforcement can be significantly reduced, while still retaining the structural performance of the PCs Corbel. This translates into less manual work and faster casting of columns.

Some of the PCs components, such as toothed surface, short headed studs and load transfer techniques are unique and have no reference in design standards. Because of this, Peikko has developed proprietary design methods. Download design tools at www.peikko.com/design-tools.

CONTACT

Peikko Group Corp.

Voimakatu 3

15101 Lahti/Finland

+358 20707-511