BAU 2017: 3D Printing, Reinforcing technology, BIM

The exhibitors of the BAU 2017 trade fair held in Munich were very pleased about the large number of attendees and the good atmosphere at the booths. According to the organizer Messe München, 250,000 visitors came to the sixteen exhibition halls, which were fully booked, during the six days of the trade fair taking place between January 16 and 21. Overall 2,120 exhibitors from 45 countries presented their products and innovations on an exhibition space covering 183,000 m².

The joint booth of InformationsZentrum Beton (IZB - Information Center Concrete), with the concrete plant partners and research institutes represented, presented a very good overview of the trends in Germany's precast production industry in the fields of building construction, underground construction, infrastructure construction and landscape and garden construction respectively as well as current research projects.

Most impressive: Two additive methods which the Technical University of Munich is currently developing for the production of concrete components; colloquially these methods are also called 3D concrete printing. The first method is an extrusion process, where lightweight aggregates such as expanded glass granulates or particles of wood, cement and water are mixed first, and then an auger, that is moved by a robotic arm, discharges the mix as small strands of fresh concrete. Laid above each other, these layered strands gradually build a structural component.

Selective binding

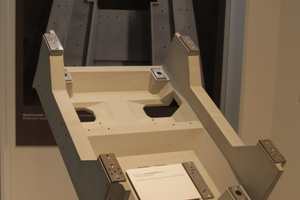

The second method is called selective binding. A layer of aggregates is spread over a surface area and only those sections of the area, where the particles of the aggregates shall bond together and where the structural component is to build up, are sprayed with a flowable cement suspension in a second working step. These steps are repeated until the component is completed; alternatively the layers spread in the first step consist of a mixture of aggregates and cement that is just wet with water in the second step, again on those sections where the component is to build up.

The twelve manufacturers of concrete elements Karl Bachl Betonwerke, R. Bayer, Concrete Rudolph, Bernhard Jäger Betonwerk, Kronimus AG, Laumer Bautechnik, Lucem, Mauthe, Quinting Zementol, REC Bauelemente, Rieder Gruppe and Schwab-Stein as well as Informationsgemeinschaft Betonwerkstein e. V. (Info-B - German Information Association for Cast Stone), the Initiative Pro Keller (German Initiative in favor of basements) and the supplier Hebau were represented at the IZB booth, too.

Exclusive products for façades

Directly opposite, the manufacturer of special cement Dyckerhoff presented their whole range of products using impressive exhibits of precast concrete – including backlit lightweight concrete panels as decorating the façade of the Al-Aziz Mosque in Abu Dhabi, elements of the wall cladding used for the six Wehrhahn-line stations in Dusseldorf, a machine bed manufactured with Dyckerhoff Nanodur compound or the seamless Terraplan concrete floor with the look of terrazzo, being especially manufactured for the BAU trade fair in the exhibition hall.

Traditionally, the suppliers of fastening and reinforcement systems to the precast concrete industry are strongly represented at the BAU trade fair. Halfen GmbH based in the German town of Langenfeld presented numerous innovations. The HEK connection elements for precast components are used to connect precast elements to each other or to adjacent components made from cast-in-situ concrete in a simple and fast way for immediate load application. Further innovations: the FPA-SL30 system for the connection of thin, large-size curtain wall façade elements and the symmetrical HIT-MVX balcony connection.

Fast, reliable connection

At their booth Peikko showcased, among others, the PCs Corbel (see video on www.bft-international.com) which has now received a national technical approval of Deutsches Institut für Bautechnik (DIBt - German Institute for Construction Technology). The corbel is a hidden connection between a reinforced concrete column and a steel beam, a Peikko Deltabeam composite beam or a precast concrete beam. The corbel is easy to install at the precast factory not requiring any special molds, just continuous straight formwork. The connection between column and beam is quickly assembled on the construction site. The fact that the PCs Corbel allows for production and erection tolerances is an advantage too; beams can be adjusted vertically, horizontally and in beam length.

The staff members at the booth of B. T. Innovation were also pleased about the large number of visitors on all exhibition days. Many product classics were displayed at the booth, including the tried and tested BT Spannschloss turnbuckle for easy, force-locked connection of precast concrete elements, the Rubber Elast sealing strip for sealing of precast component joints as well as the ultra-light MagFly AP magnet system featuring an outstanding adhesive force to weight ratio or the lightweight FlyFrame shuttering support.

A glance into the virtual future of construction

Reckli, the manufacturer of formliners, also reported about large crowds at the booth. The formliners of the company located in the German town of Herne allow decorating surfaces of concrete façades with almost any pattern. An outstanding reference at this year's booth: the NOSPR concert hall in the Polish city of Katowice; Reckli supplied the formliner for the wave-like texture on the black concrete elements used as cladding of the interior walls of the impressive concert hall. Another highlight: By means of virtual reality goggles and excellent graphics, the attendees of the booth could get a picture of the design a façade would get by their respectively favored formliner.

The visitors could also take to glance into the future of construction in hall C3, where the software providers informed on latest topics, including Building Information Modeling (BIM) or augmented reality that is additional information generated by the computer as supplement to reality. At the booth of Trimble visitors could experience a new version of the SketchUp Viewer software using Microsoft HoloLens. Wearing the device one looks, for example, at a building existing in reality and SketchUp supplements this real building by a virtual extension, which is imported by Microsoft HoloLens and displayed in the wearer's field of view. The architect Greg Lynn made use of the technology in order to create his design for the conversion of the former Packard Automobile Plant in Detroit and to discuss it with his clients.

The next edition of the BAU trade fair - BAU 2019 - will take place at the Messe München trade fair center from January 14 to 19, 2019. Then the trade fair center will be extended by two new halls covering an overall exhibition space of 200,000 m².

Text: Christian Jahn, M.A.

CONTACT

Messe München GmbH

Messegelände

81823 Munich/Germany

+49 89 949-20720