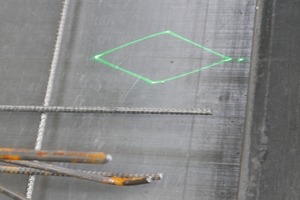

Laser projectors optimize pallet assembly in a carousel system

The requirements made on the production of precast components are constantly rising: walls and floors become more complex, delivery times shorter, “last minute” changes are the order of the day. Nevertheless, the customers of precast plants have every right to expect high quality and dimensional accuracy. At the precast plant of Betonwerk Bürkle, laser projectors facilitate many workflows involved in the manual placement of forms and embedded parts on pallets in carousel systems.

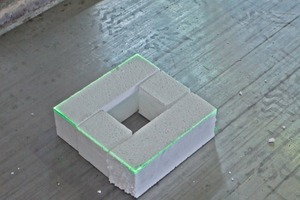

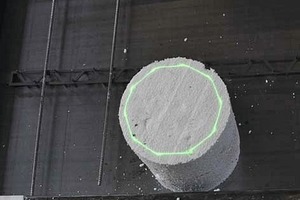

Laser projectors generate “optical templates” on the work surface that enable rapid and exact positioning of the various parts and that ensure the dimensional accuracy of the completed precast components.

Exact positioning of the parts is of crucial significance when placing the forms and embedded parts required for the manufacture of precast components on rotating pallets. The positions of embedded parts and blockouts have to be exactly marked. This is the only way to ensure the dimensional accuracy of the components to be manufactured. But the manual calibration and the marking of...