All-rounder with half the cycle time and reduced set-up time

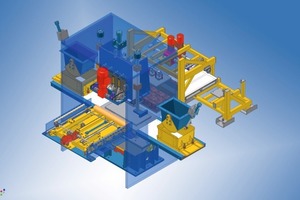

The new development of the RMM multifunction machine aimed at integrating the wide range of final products as well as short cycle and set-up times in one machine at the same time. For existing equipment this provides new possibilities as extension or attachment to an existing block making machine or slab making circulation systems. There is also an entry-level model available of the machine for newly built plants. As an extension, it may be a real alternative to block making machines, turntables, and sliding beds.

The multifunctionality is considered to be the biggest benefit of the equipment according to the manufacturer, who is already operating in international markets with the RSM sliding bed machine and the RTM turntable machine. The first requirement for multifunction applications is the flexibility in height of the machine and the molds. As standard values heights of 2 up to 8 cm or 4 up to 10 cm are offered, or up to 22 cm as an option. The differences in height of 6 up to 8 cm can be adjusted from the operator‘s panel. A filling level adjustment in the range of 0.1 mm is even possible.

The...