Raknor LLC counts on RH 1,500 MVA block machine

Raknor LLC, a manufacturer of high-quality concrete products that has been well-established in the United Arab Emirates for many years now, has decided in favor of a complete production line of the Hess Group when it came to re-equip the concrete block making machines recently.

Raknor LLC, the manufacturer of concrete blocks that has been located in the Emirate of Ras Al Khaimah for four decades now, is primarily specialized in products of high quality for the domestic construction industry. According to the company’s own statement, before the re-equipment, Raknor had been manufacturing on two existing production lines equipped with machines from Columbia and Masa. The parent company of Raknor, Stevin Rock L.L.C., that is operating several quarries in the United Arab Emirates, played a leading role in awarding a contract to the Hess Group headquartered in Burbach for new equipment technology.

High-quality concrete blocks for 40 years

“Growth is the key to our success, therefore, we will continue to expand in future. We are very pleased that we have found two reliable partners with the Hess Group and their associated company SR-Schindler, supporting us with help and advice to expand our product portfolio. We have taken the first step with the installation of the new concrete block making equipment. However, to be well prepared for the future, we have to take the many different options of concrete block treatment into account too. Therefore, it was important for us to select a machinery supplier like the Top-Werk Group that is not only manufacturing concrete block machines but also machines for surface treatment of concrete blocks,” Bernard Regin, factory manager of Raknor, stated.

Talking about the selection of the supplier, Regin continued to explain that Raknor above all attached great importance to an excellent service which Hess Middle East provided by its own service center, being distinguished by flat hierarchies and fast decision-making: “Hence, we can rely on the best trained service staff of Hess Middle East at any time. In this way, we get the best performance out of the equipment.”

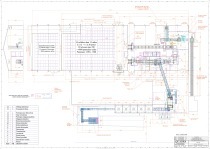

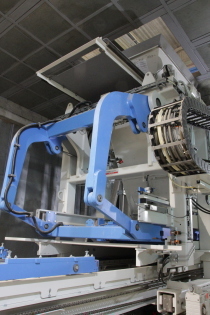

Multimat RH 1,500-3 MVA core part of the system

The Multimat RH 1,500-3MVA concrete block machine with face mix unit is the core of the Hess system. The machine is furnished with MAC 8 hydraulic system, precisely monitoring and controlling all axes of the tamper head, the mold and the filler box. The individual axes are more accurately adjusted to each other as against conventional control systems, finally resulting in faster movements, shorter cycle times as well as improved running smoothness, as stated by the manufacturer. This provides for lower wear and reduced maintenance requirements.

Raknor chose, as further option, the VarioTronic vibration system controlled by servo motors together with oil-bath vibration. The fully electronic control system impresses with high reliability and repeat accuracy. Frequency or amplitude can be adjusted individually, thus ensuring optimum vibration parameters and results both during mold filling and the main compaction process. This again leads to shorter vibration times and consistently high product quality simultaneously. As the vibrating shafts are individually mounted in closed housings filled with oil, they are permanently lubricated which is reflected in a longer service life. Moreover, the vibrators can be replaced individually for maintenance. Hence, it is not necessary to disassemble the entire vibration table completely.

A V-belt conveyor is transporting the freshly produced blocks to the elevator in a smooth way and without any dead time of the concrete block machine. The single-discharge system with 20 racks is designed to carry a maximum load of 14 tons. After transferring to the finger car, the products are placed into the rack storage facility of Rotho for drying. The single atmosphere chamber is furnished with a circulation system of Rotho. After curing, the finger car and lowerator carry the blocks to the cubing station. Here the 700-kg cubing system with servo motor is acting with electrically operated gripper. Consequently, elaborate maintenance, which is usual for oil circulations, is eliminated.

Complete mixing plant supplied from Burbach

As far as the concrete mixing systems are concerned, Raknor also relies on the Hess company, that has been carrying out the mixing systems at the company headquarters in Burbach since the integration in the Top-Werk Group. For mixing core concrete Raknor uses the newly conceived SM 2,250-3 compulsory mixer. The separate motors of the mixer with a maximum filling capacity of 2,250 liters provide for a fast and efficient mixing process through planetary-like rotary motions. This not only reduces the energy demand and wear, but also enables stopping and starting the mixer even if filled with the maximum batch capacity. Large doors on both sides facilitate, moreover, cleaning and maintenance of the mixing plant. An additional fast discharging system inside the mixer vessel provides for shorter cycle times. The SP SX500 mixer is used for the face mix concrete.

Control system concept fully revised

In addition, the Hess Group’s specialists have fully revised the control system concept of the concrete block machines and the concrete mixing plant. Now, touch panels are exclusively used on the basis of the Siemens S7 control system. By using the uniform control system concept not only operation as a whole is more user-friendly, but also training periods are reduced considerably. The new Hess manufacturing statistics, moreover, allow the owner of the plant to have direct access to the current production data from anywhere in the world so as to respond accordingly. A web-based app enables monitoring orders, shifts, personnel, number of items or downtimes, using a smart phone or tablet.