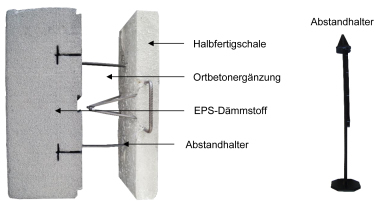

Two-layer precast element consisting of aerated concrete and a heat-insulating calcium silicate material

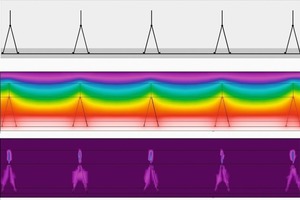

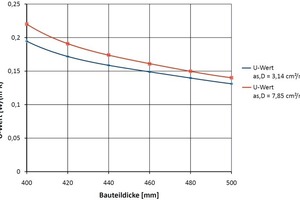

The ever-stricter requirements imposed on heat insulation, the thermal benefits of solid building materials (in particular aerated concrete) and the efforts undertaken to streamline construction processes gave rise to the development of a structural composite element including a highly insulating calcium silicate material to be used for prefabricated roofs in residential and commercial construction. This article presents the outcomes of this project.

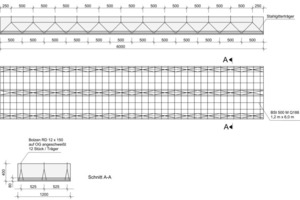

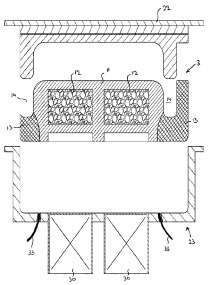

The aim was to develop a precast element that consisted of two layers: a solid aerated concrete layer and a highly insulating, thicker layer consisting of lower-strength aerated concrete. The element was to be manufactured on steel molds at the AAC plant in horizontal position, using the so-called pan casting process. The particular feature of this method is that the product is manufactured in a “wet-in-wet” process. Following the expansion of the layers, the element is cured in the autoclave.

Background

The heat insulation specifications for structural elements have become more demanding ever...