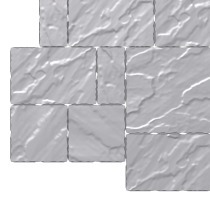

Molds for the Precast Industry

Very „quick“ explosives with a special geometry / consistency are excellently qualified for the deformation of sheet metals and/or for providing beads either freehanded or guided, without tamper/die, i.e. shape accuracy without the need of adjustment. Using this direct method Sprengtechnik Rieger realized reflexively quick, individual casting molds at an extremely favorable price that are generally made of stainless steel sheets, and thus helps explosive materials to be accepted in the industry.

The method can definitely be compared to the conventional deep-drawing, however the tamper is replaced by explosives, and the drawing die by a sand bed or a flexural bottom. It is furthermore different to deep-drawing due to the fact that the blank areas can be redrawn or drawn in with just minor sheet thickness loss. Owing to the extreme deformation and/or forming speed (within milliseconds) the material needed for formation has to be obtained directly and locally from the deformation zone (by unwinding).

When the deformation process and/or texturing begins the plastic deformation commences...