Concrete more concrete

At this year’s Dornburger Construction Themes, held under the motto “Concrete more concrete,” Dornburger Zement business managers Eckhardt Thomas and Heiko Theuerkauf welcomed more than 120 customers and partners at the company event site in Weimar, Germany.

Thomas Richter (Dr.-Ing.) of BetonMarketing Ost GmbH opened the program of lectures. “New solutions for an old problem” was his title for a compilation of historical and current damage analyses of bridge caps in Germany.

Expensive repair

The fact is strikingly apparent that some elements that protect the loadbearing structure from the stresses imposed by the environment and by utilization must often be repaired at high cost after only a few years, while others survive many years largely without damage. The results of earlier and current investigations do not indicate a relationship between the degree of damage and the cement type, concrete strength class, or the type of admixtures used. There are, however, indications of the influence of manufacturing conditions (especially curing), the age of the concrete at the time of the first exposure to salt, the number and intensity of freeze-thaw cycles, and the amounts of thawing agent used.

In the lecture, the DBV-/VDB code of practice “Bridge caps made of concrete” and its essential content was presented as state of the art.

Plastic – more than an alternative to steel fibers?

Dr. Klaus-Alexander Rieder from the company Grace Bauprodukte GmbH explained in his lecture the properties of plastic fibers compared to steel fibers and the basic constraints involved. In particular, the mechanical performance of macro fibers with their relatively high modulus of elasticity of approx. 10 GPa is very similar to that of most steel fibers.

However, the specific properties of plastic fibers considerably broaden the areas of application of fiber concretes. Worthy of particular note is their high resistance to chemical attacks on concrete. They are ideally suited for use in concrete for animal-stable facilities, biogas containers, and wastewater treatment plants. Their use is also highly effective for all applications where corrosion of steel fibers near the concrete surface mars the outer appearance of concrete. The absence of electrical conductivity and inability of being magnetized are sure to generate additional possibilities of application.

The outstanding properties of macro plastic fibers have been proven under actual traffic and environmental conditions in exemplary road-construction applications: for example, involving whitetopping with thin concrete layers manufactured with these plastic fibers.

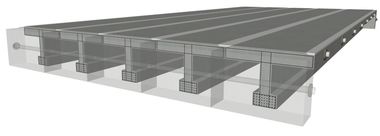

Schmidtstedter Junction: Exciting concrete giant

Engineer Klaus Vogt (Ing.) of the company BFE Beton Fertigteilbau Erfurt GmbH impressively demonstrated the performance capability of his company by showing the example of a girder required for widening the lane of the bridge at the Schmidtstedter Junction near Erfurt, Germany. With a length of 21 m and an overall weight of 136 tons, the structure is a real concrete giant.

Klaus Vogel, during his presentation, expressed his gratitude for the support of the dornburger zement competence center. Without the ultrasound measurement in the hardened component it would have been impossible to determine the exact point of time for determining the safe lifting strength of at least 32 N/mm². Given the high self-weight of the member it was of utmost importance for all fastening devices in the concrete to stay firmly in place, one hundred percent – here, there was no second test!

Sustainable and high-performance concretes – two worlds?

Technical and economic constraints have always been the driving force behind the development of construction materials and civil engineering. Professor Horst-Michael Ludwig (Dr.-Ing.), Director of the F.A. Finger Institute for Construction Materials Science at Bauhaus University in Weimar, Germany, emphasized that ecological aspects are now exerting additional pressure on the development of construction materials and civil engineering.

Prof. Ludwig discussed in particular the future role of eco balances and environmental declarations, as well as of the environmentally sound manufacture of cement. Today, CEM II cements made with granulated blastfurnace slag, limestone, or both components, have at least physical properties that are equivalent to CEM I cements. In terms of their durability – e.g., carbonation and resistance to freeze-thaw cycles with de-icing salt – concrete made with such cement even shows appreciably enhanced potential qualities. Prof. Ludwig demonstrated these advantages by showing the results of investigations conducted at the F.A. Finger Institute. Sustainability and durability – are therefore not really two different worlds.