Dürnbach bridge pilot project – Germany’s first precast railway bridge made of UHPC, part 1

Ultra-high performance fiber-reinforced concrete (UHPFRC) is characterized by an extremely dense structure and thus very high strengths as well as excellent durability properties. This enables slender construction in a material-saving and weight-reduced way, opening up completely new possibilities and applications in the field of precast concrete construction.

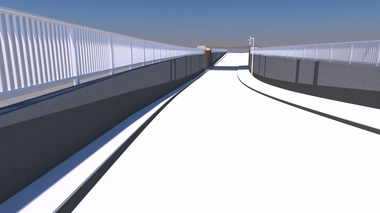

In the course of the renewal of the superstructure of an existing railway bridge of the Tegernseebahn network, the material could be used for the first time particularly purposeful and advantageous for the construction of a railway bridge. Hence, using UHPFRC allowed the realization of a slender structure with a very low construction height which was lifted in as a comparatively light overall precast element during a short track closure break. The 4.57 m wide and 6.50 m long superstructure was designed as a trough-shaped precast slab bridge made of prestressed concrete elements and could be designed with a slab thickness of only 20 cm. An UHPFRC of class C150/155 with 2.5 vol.-% of micro steel fibers was used for the superstructure. An expert’s report was furnished to obtain an approval on a case-by-case basis; this report (carried out on the basis of the current draft of the DAfStb Code of Practice) defines corresponding rules of application for the use of UHPFRC. As part of the project, moreover, measurement supervision and scientific support were carried out during production as well as during the ongoing railway operation.

The conception of the solution, the expert opinion, the conceptual design and the constructional inspection was carried out by the Chair of Concrete and Masonry Structures of TUM in cooperation with the engineering office Büchting+Streit AG, the detailed design was conducted by the engineering office SSF Ingenieure AG. Max Bögl was commissioned with the production of the precast elements, using UHPC Compound of HeidelbergCement AG.